HHD DELTA RL4-1600-12kg

Delivery time: max. 12-14 weeks after order confirmation (For larger quantities please contact us. The delivery time specification also applies to spare parts.)

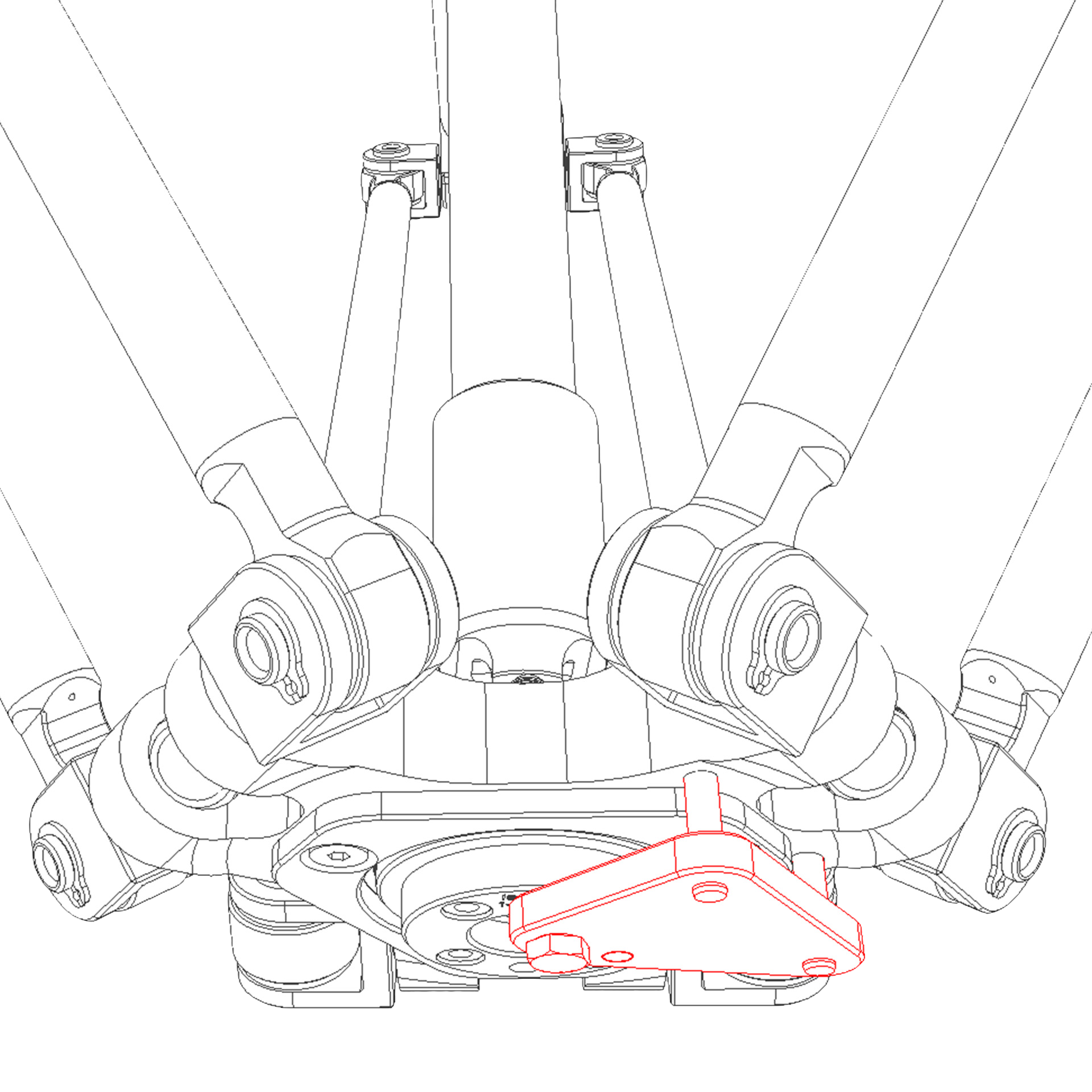

This type of robot is based on the principle of parallel kinematics.

All drives are mounted in a fixed position on the robot head. Motor cables are not moved. The robot has three (3) translational and one (1) rotational degree(s) of freedom.

Scope of delivery

- Robot mechanics incl. gearbox

- Servo motor adapter

- Transport and packing instructions

Note: The operating instructions and documentation on commissioning, service, maintenance, etc. are available in the password-protected download area of the respective product page (www.autonoxfinder.com).

-

Signed in / logged in you will receive further documents:

Note: If the documentation in the download area is not yet complete, please contact us (info@autonox.com).

| Field of application: | Hygienic ′HHD′ |

|---|---|

| Kinematics: | Parallel |

| Translatory Degrees of Freedom (X,Y,Z): | 3 |

| Rotational Degrees of Freedom (α,ß,γ): | 1 |

| Nominal payload [kg|lbs]: | 12 | 26.5 |

| Working area-diameter [mm|in]: | 1600 | 63.0 |

| Working height outside [mm|in]: | 325 | 12.8 |

| Working height center [mm|in]: | 541 | 21.3 |

| Max. acceleration torque of the rotation γ around Z at the output [Nm|in.lbs]: | 110 | 973.6 |

| Nominal torque of the rotation γ around Z at the output [Nm|in.lbs]: | 110 | 973.6 |

| Max. speed of the rotation γ around Z at the output [1/min]: | 260 |

| Nominal speed of the rotation γ around Z at the output [1/min]: | 160 |

| Bearing type of the telescopic shaft(s): | Roller bearing |

| Bearing type of the arm joints: | Roller bearing |

| Lubricants of the bearings: | Food-grade (FO) |

| Lubricants of the gearboxes: | Food-grade (FO) |

| Cleaning: | Up to 28 bar | 406 psi high pressure |

| Protection class: | IP69K |

| Ambient temperature [°C|°F]: | 0 to +40 | +32 to +104 |

| Relative humidity level [%]: | 95 (free of condensation) |

| Mounting position: | Ceiling, Wall (on request), Angle (on request) |

| Special features: | With stainless steel gearboxes (food-grade lubricants, but therefore reduced performance). |

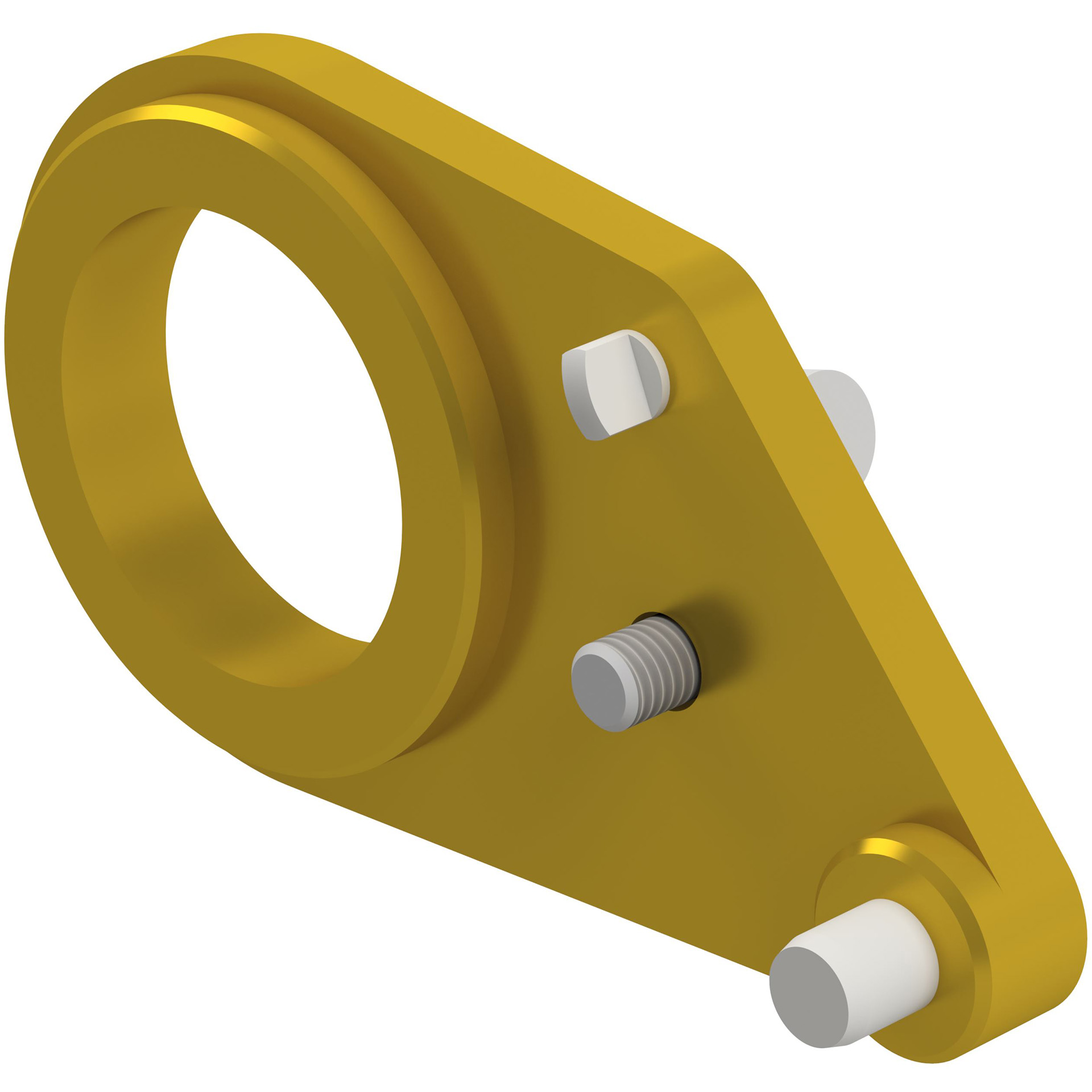

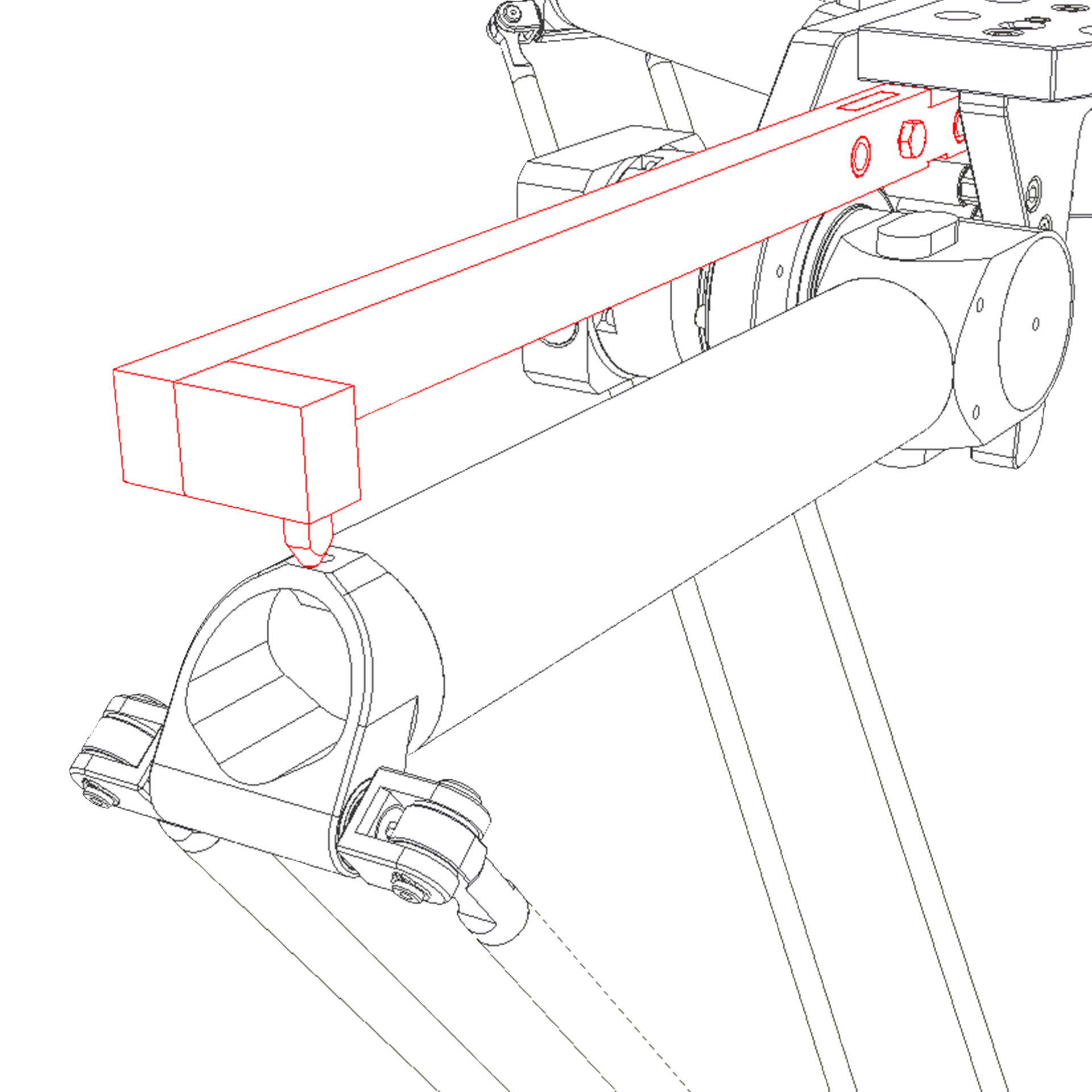

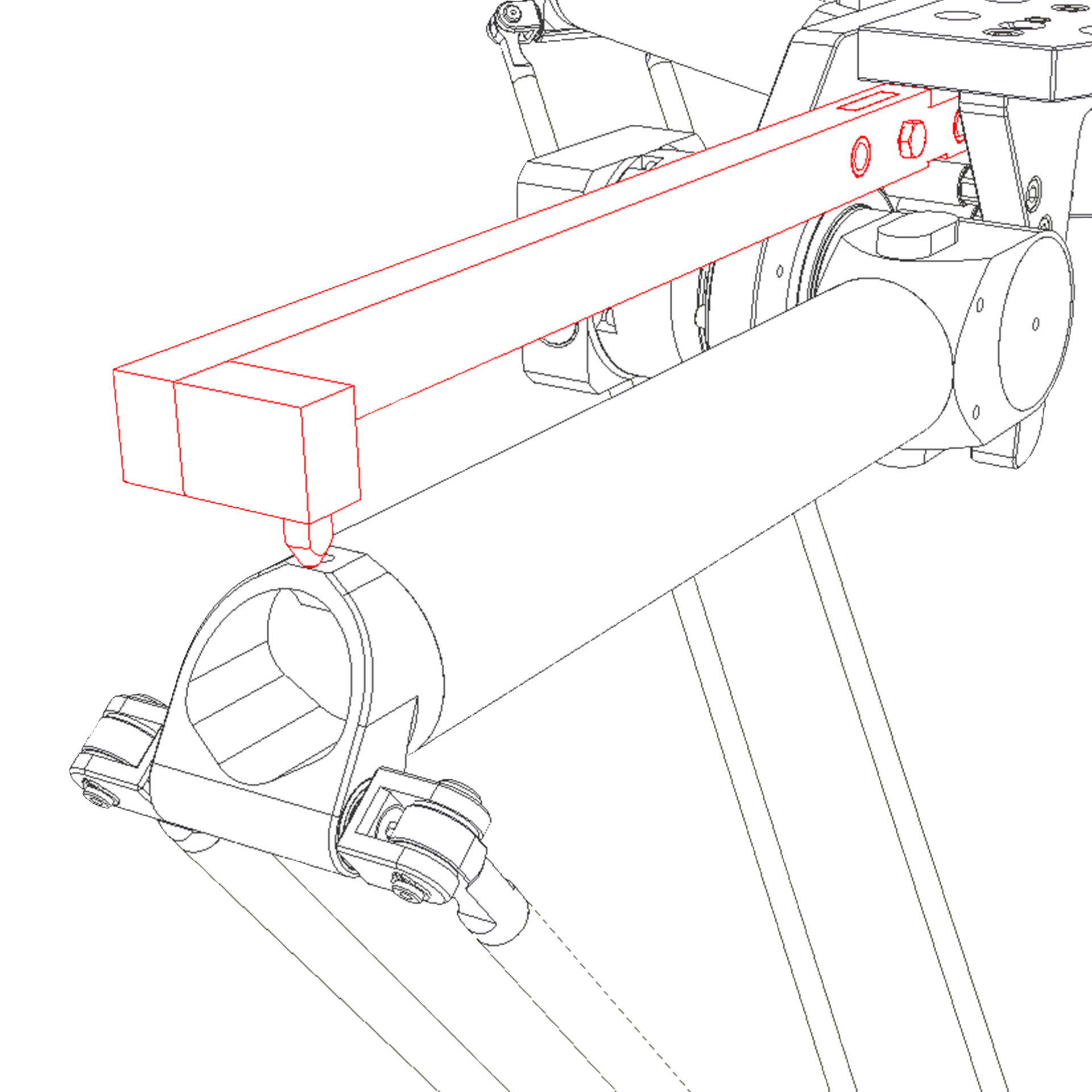

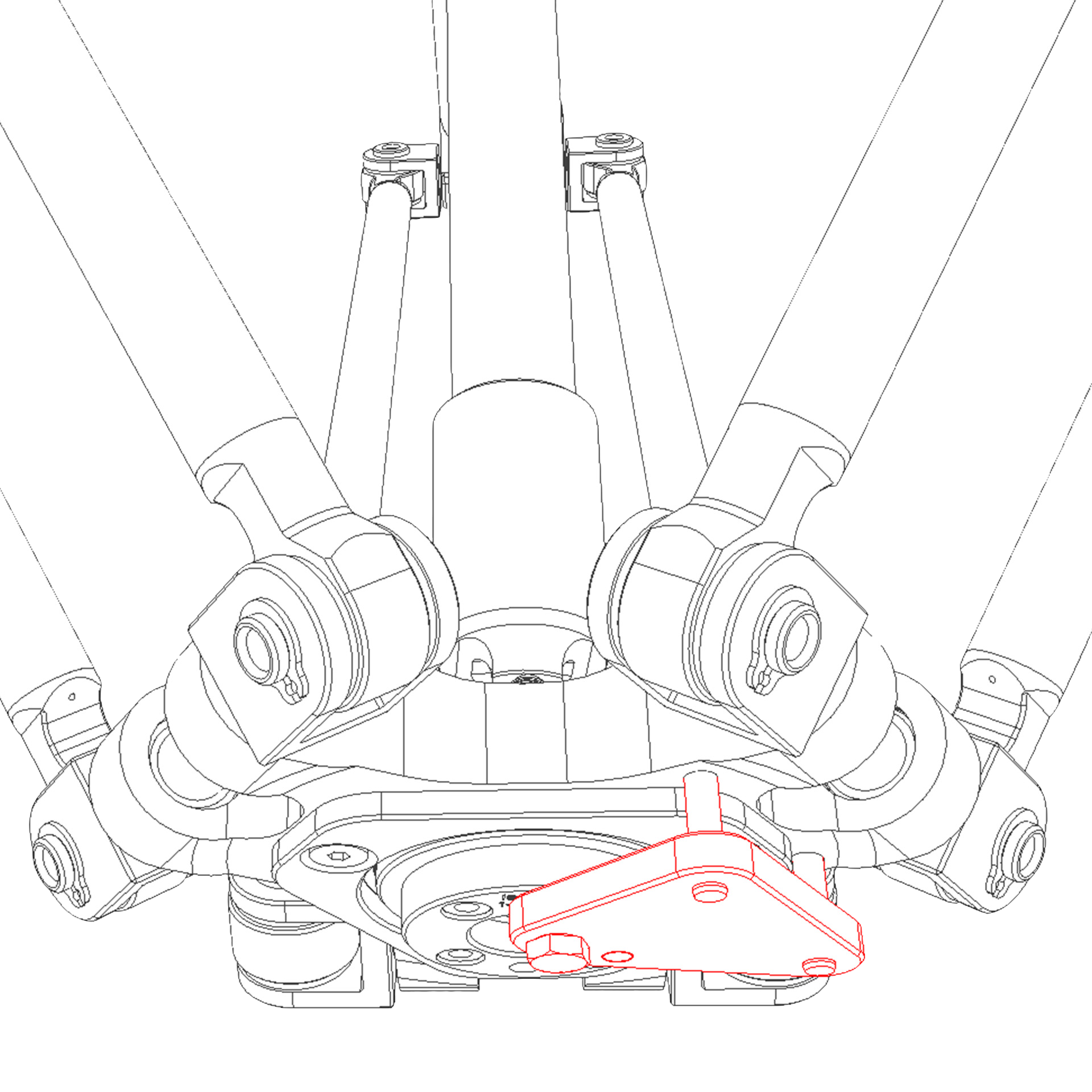

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This type of robot is based on the principle of parallel kinematics.

All drives are mounted in a fixed position on the robot head. Motor cables are not moved. The robot has three (3) translational and one (1) rotational degree(s) of freedom.

Scope of delivery

- Robot mechanics incl. gearbox

- Servo motor adapter

- Transport and packing instructions

Note: The operating instructions and documentation on commissioning, service, maintenance, etc. are available in the password-protected download area of the respective product page (www.autonoxfinder.com).

| Field of application: | Hygienic ′HHD′ |

|---|---|

| Kinematics: | Parallel |

| Translatory Degrees of Freedom (X,Y,Z): | 3 |

| Rotational Degrees of Freedom (α,ß,γ): | 1 |

| Nominal payload [kg|lbs]: | 12 | 26.5 |

| Working area-diameter [mm|in]: | 1600 | 63.0 |

| Working height outside [mm|in]: | 325 | 12.8 |

| Working height center [mm|in]: | 541 | 21.3 |

| Max. acceleration torque of the rotation γ around Z at the output [Nm|in.lbs]: | 110 | 973.6 |

| Nominal torque of the rotation γ around Z at the output [Nm|in.lbs]: | 110 | 973.6 |

| Max. speed of the rotation γ around Z at the output [1/min]: | 260 |

| Nominal speed of the rotation γ around Z at the output [1/min]: | 160 |

| Bearing type of the telescopic shaft(s): | Roller bearing |

| Bearing type of the arm joints: | Roller bearing |

| Lubricants of the bearings: | Food-grade (FO) |

| Lubricants of the gearboxes: | Food-grade (FO) |

| Cleaning: | Up to 28 bar | 406 psi high pressure |

| Protection class: | IP69K |

| Ambient temperature [°C|°F]: | 0 to +40 | +32 to +104 |

| Relative humidity level [%]: | 95 (free of condensation) |

| Mounting position: | Ceiling, Wall (on request), Angle (on request) |

| Special features: | With stainless steel gearboxes (food-grade lubricants, but therefore reduced performance). |

-

Signed in / logged in you will receive further documents:

Note: If the documentation in the download area is not yet complete, please contact us (info@autonox.com).

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))