| Parallel Kinematics | Serial Kinematics | |

|---|---|---|

| COMPARISON OF KINEMATIC MODELS |

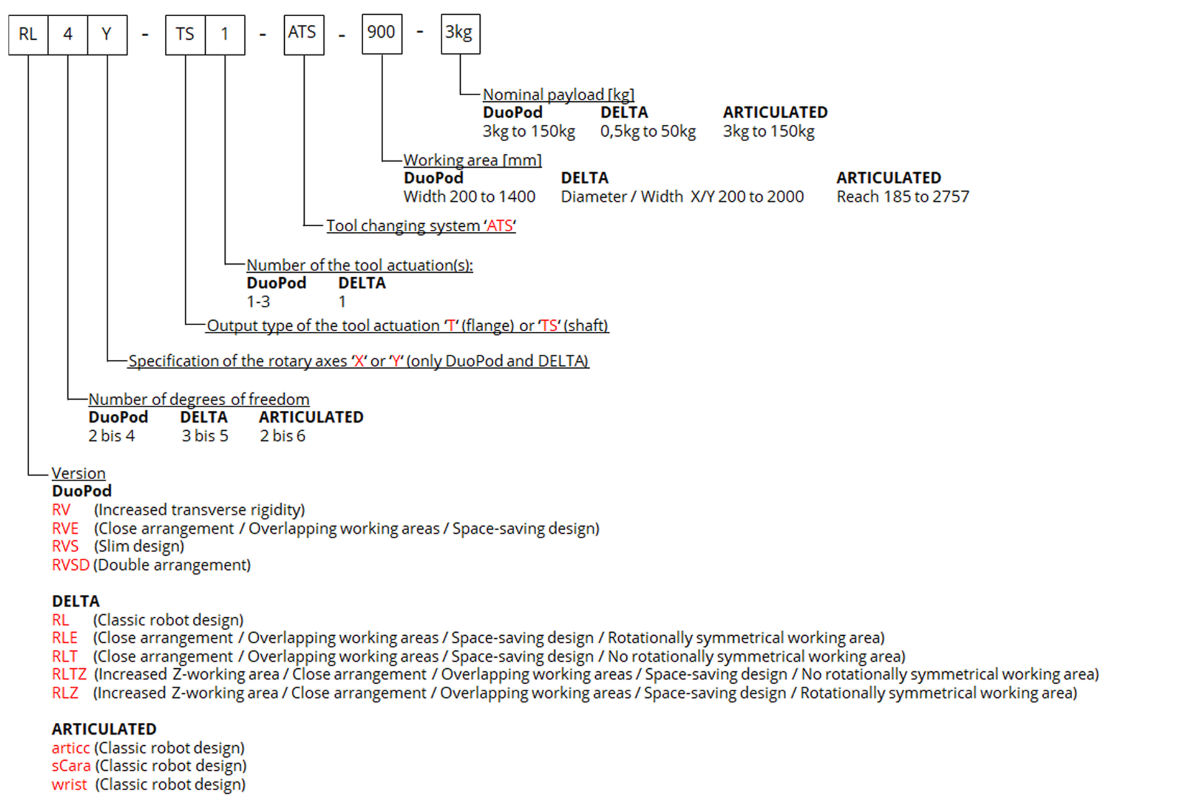

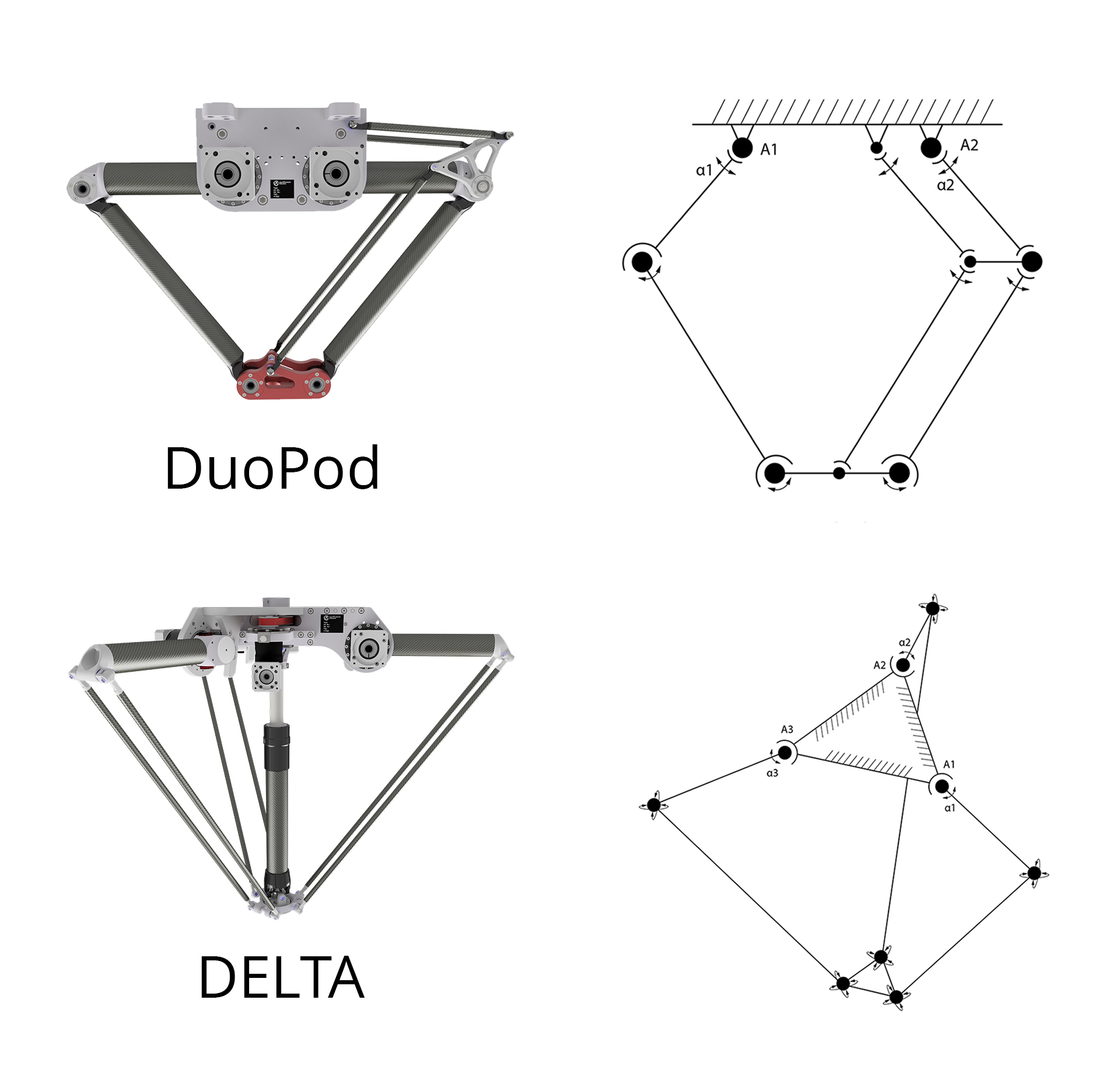

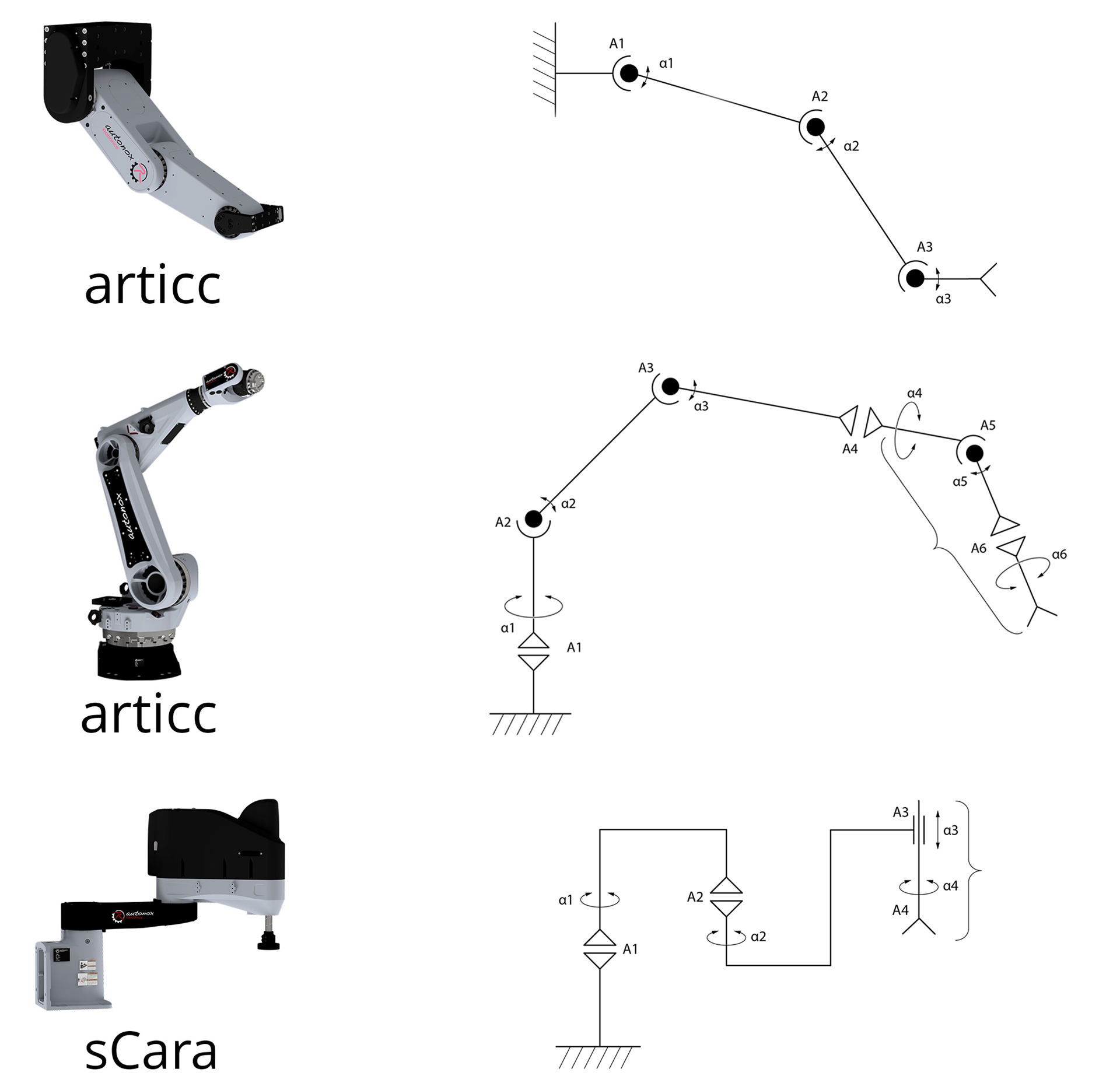

In robotics, a distinction is made between the main classes of serial and parallel kinematics. While serial kinematics consist of a string of arm parts,

in the case of a parallel robot several sliding joints act directly on the moving tool holder. Due to the direct connection of each drive to the tool holder, these are not loaded with the masses

of the subsequent links and drives as in the case of serial kinematics. The resulting low level of moving dead weight makes extremely dynamic movement possible, combined with a high level of precision of the mechanics. Recommendation: Use parallel kinematics if the degrees of freedom, the nominal payload and the working area are sufficient for the application. |

|

| Types: |  |

|

| Number of degrees of freedom DoF: | + | |

| Rotational swivel areas: | + | |

| Complex trajectories: | + | |

| High nominal payloads (> 50kg): | + | |

| Large working areas (> 2.000 mm): | + | |

| Robot mechanics causes small interference contour outside its working area: | + | |

| Total mass of robot mechanics: | + | |

| Low moving dead weight: | + | |

| Dynamics: | + | |

| Energy balance: | + | |

| Maintenance requirements (including motor cables): | + | |

| Susceptibility to damage (especially hand axes) after a collision: | + | |

| Serviceability: | + | |

| Availability: | + | |

| Flexible mounting position: | + | |

| Extreme ambient conditions: | + | |