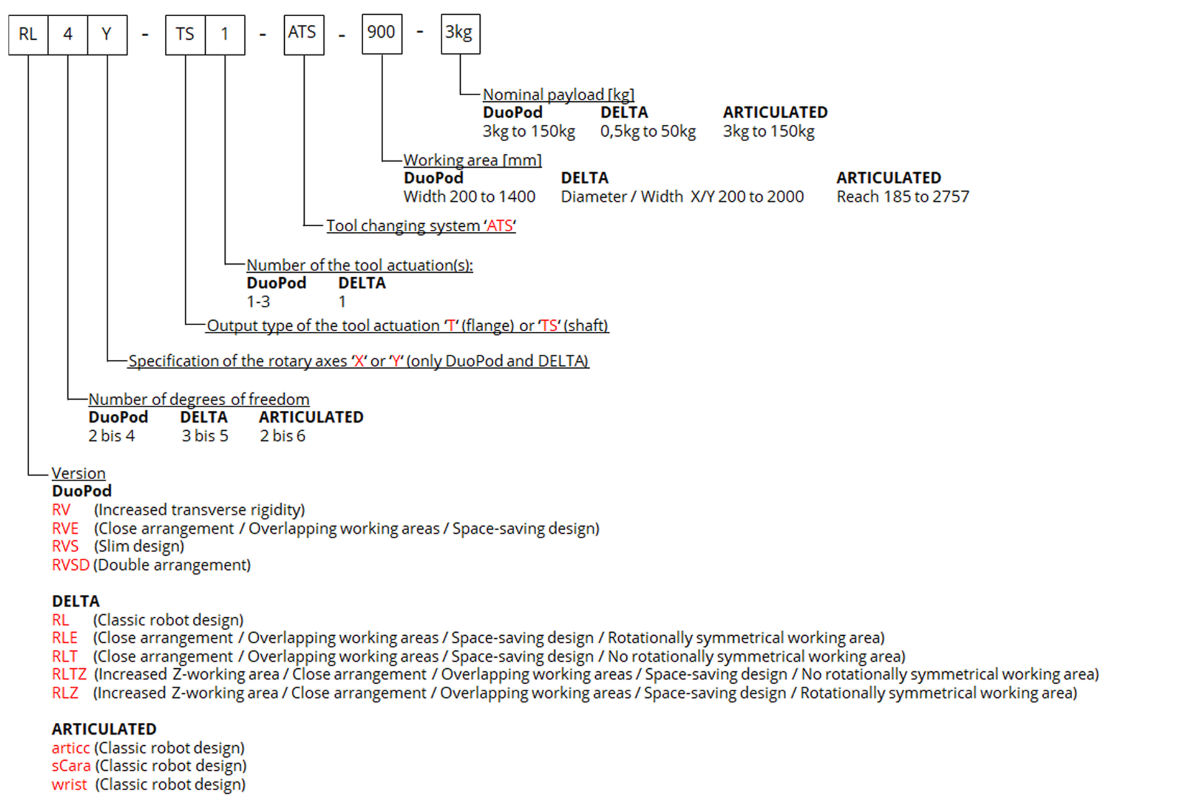

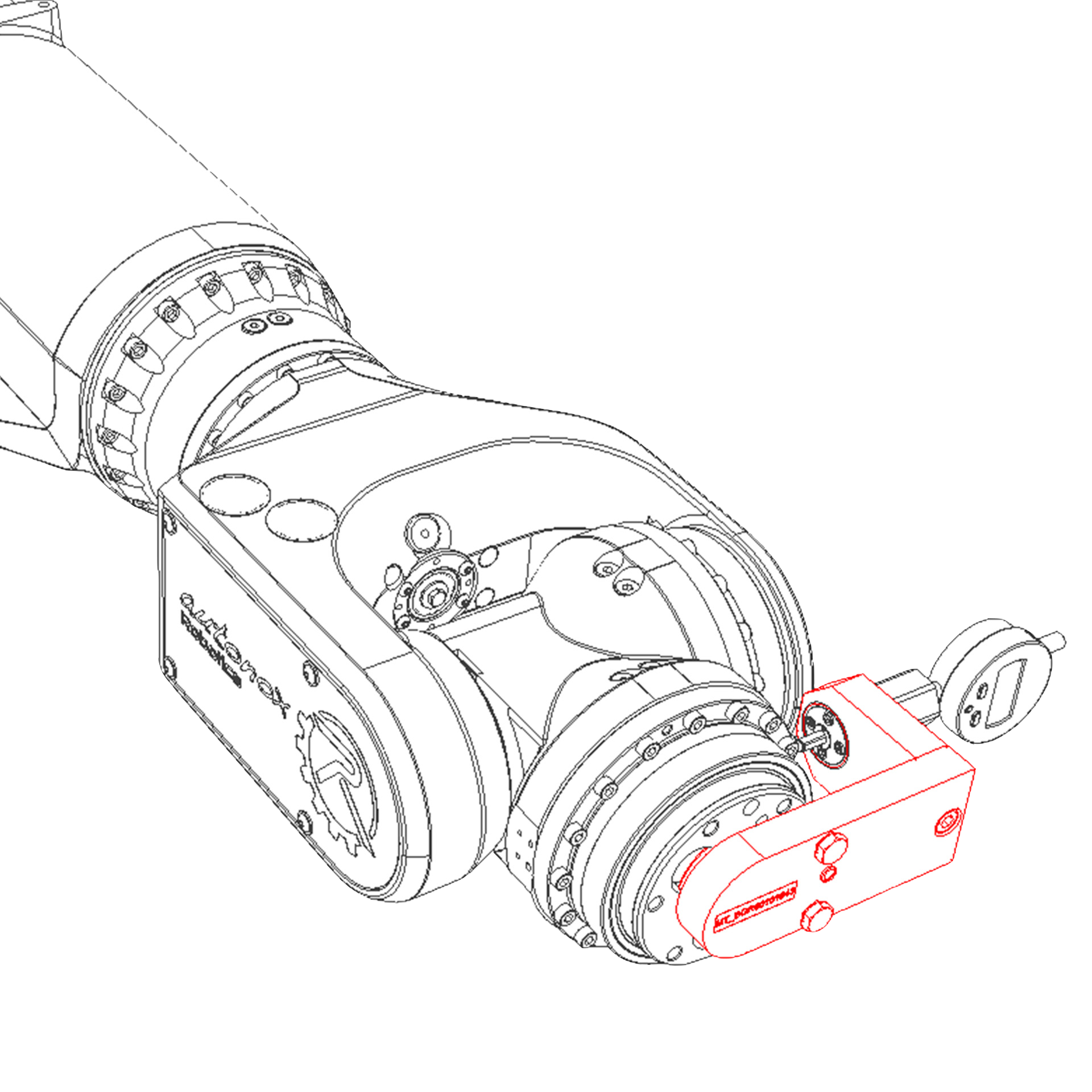

ARTICULATED articc.m6-2390-150kg

Delivery time: on request

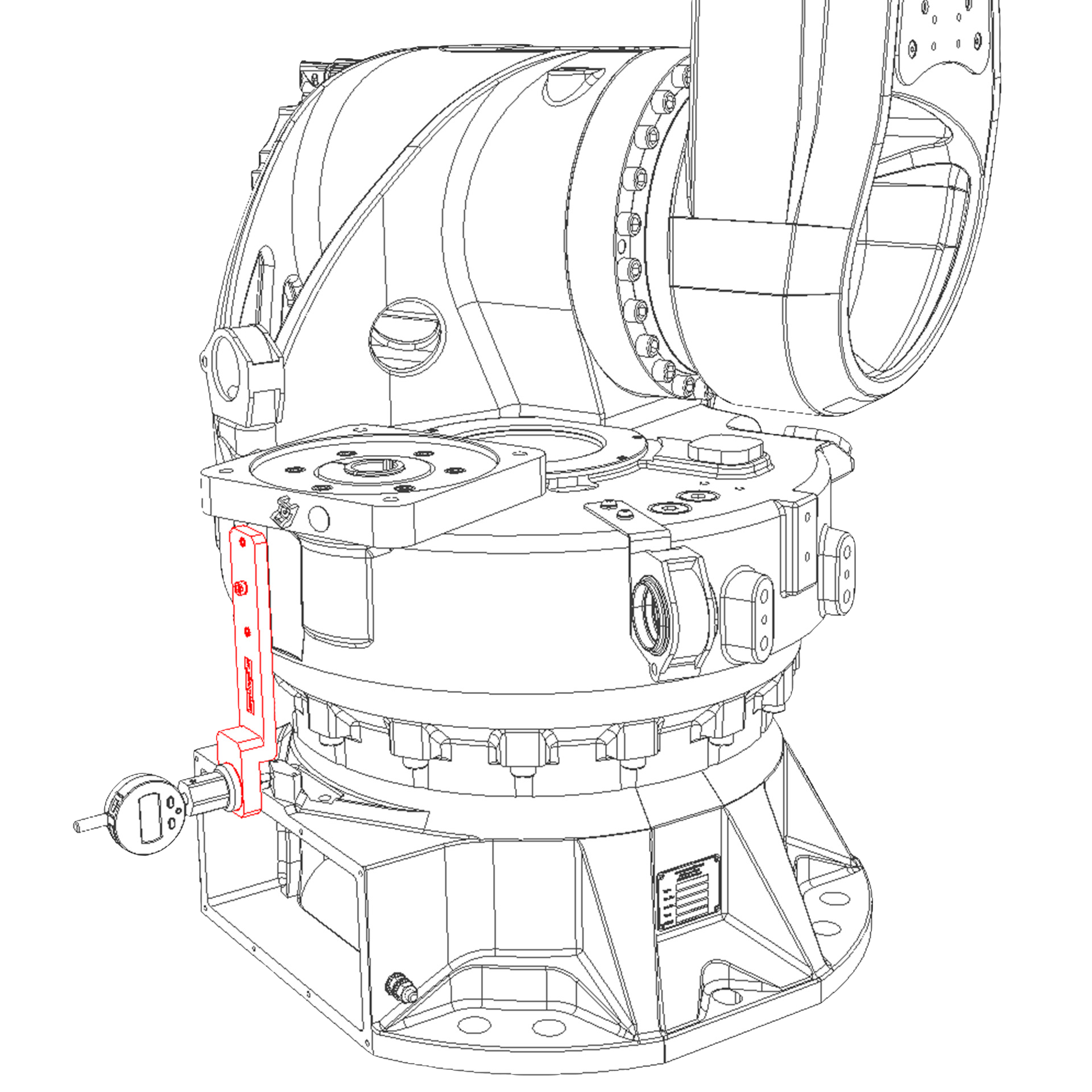

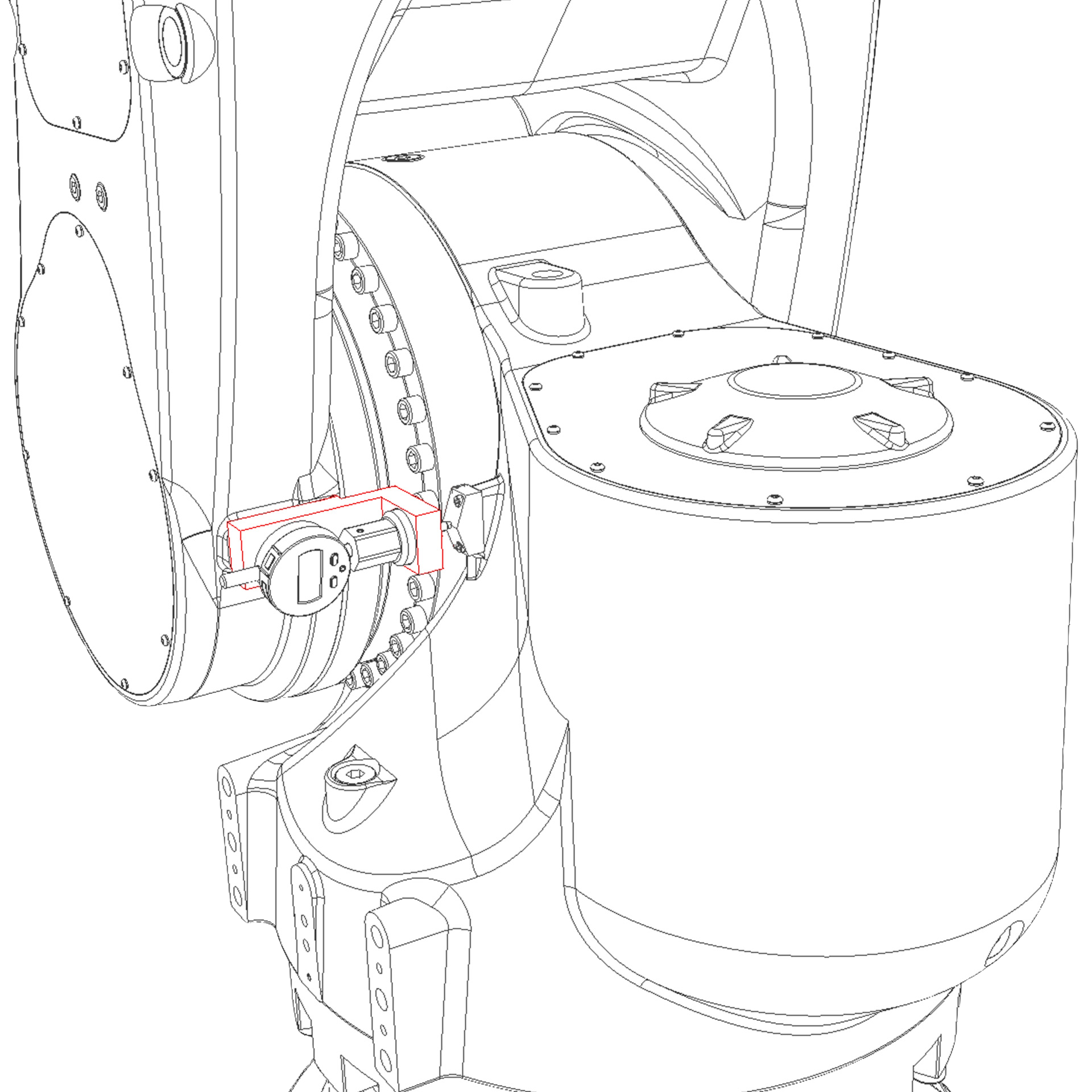

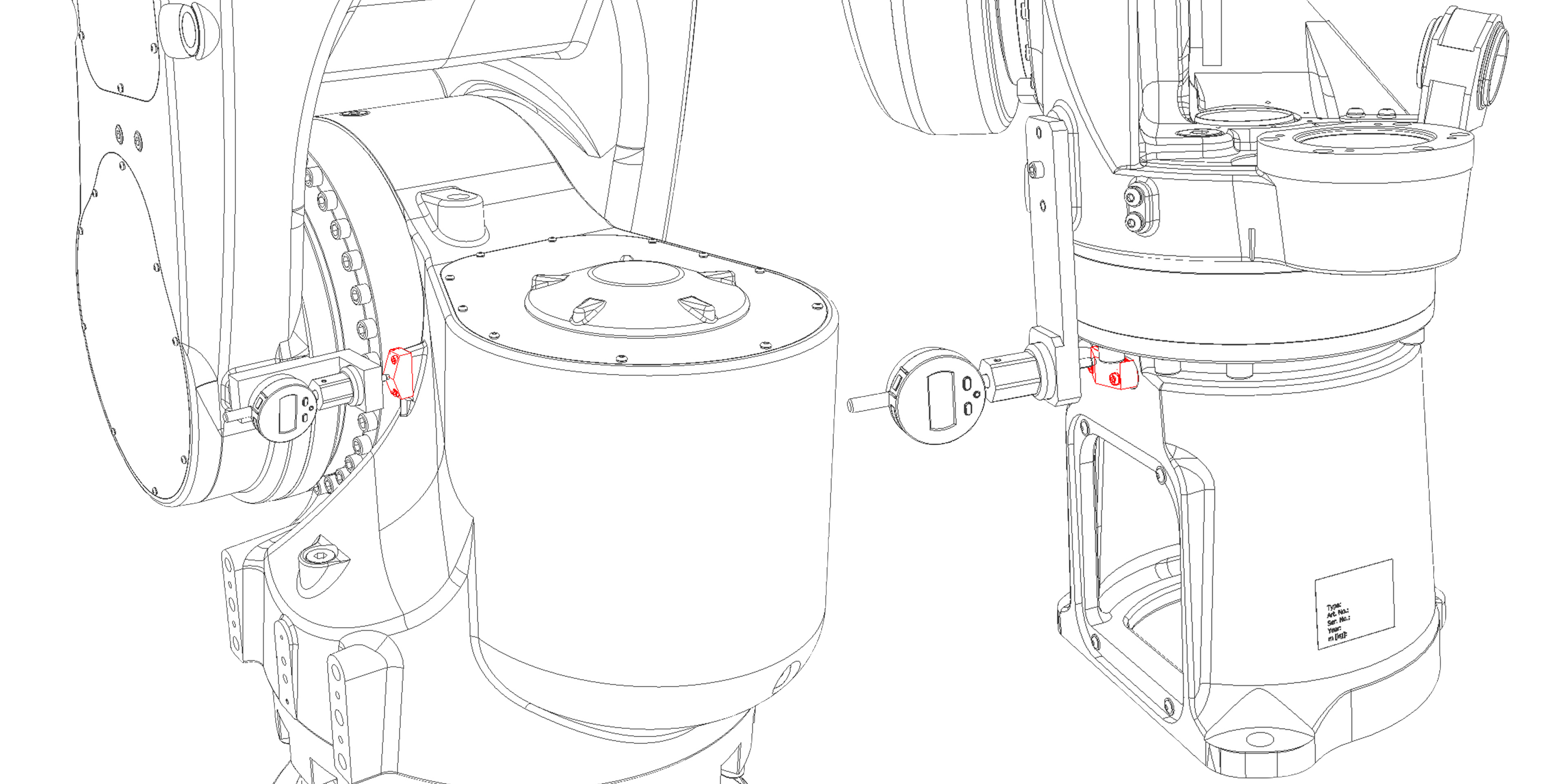

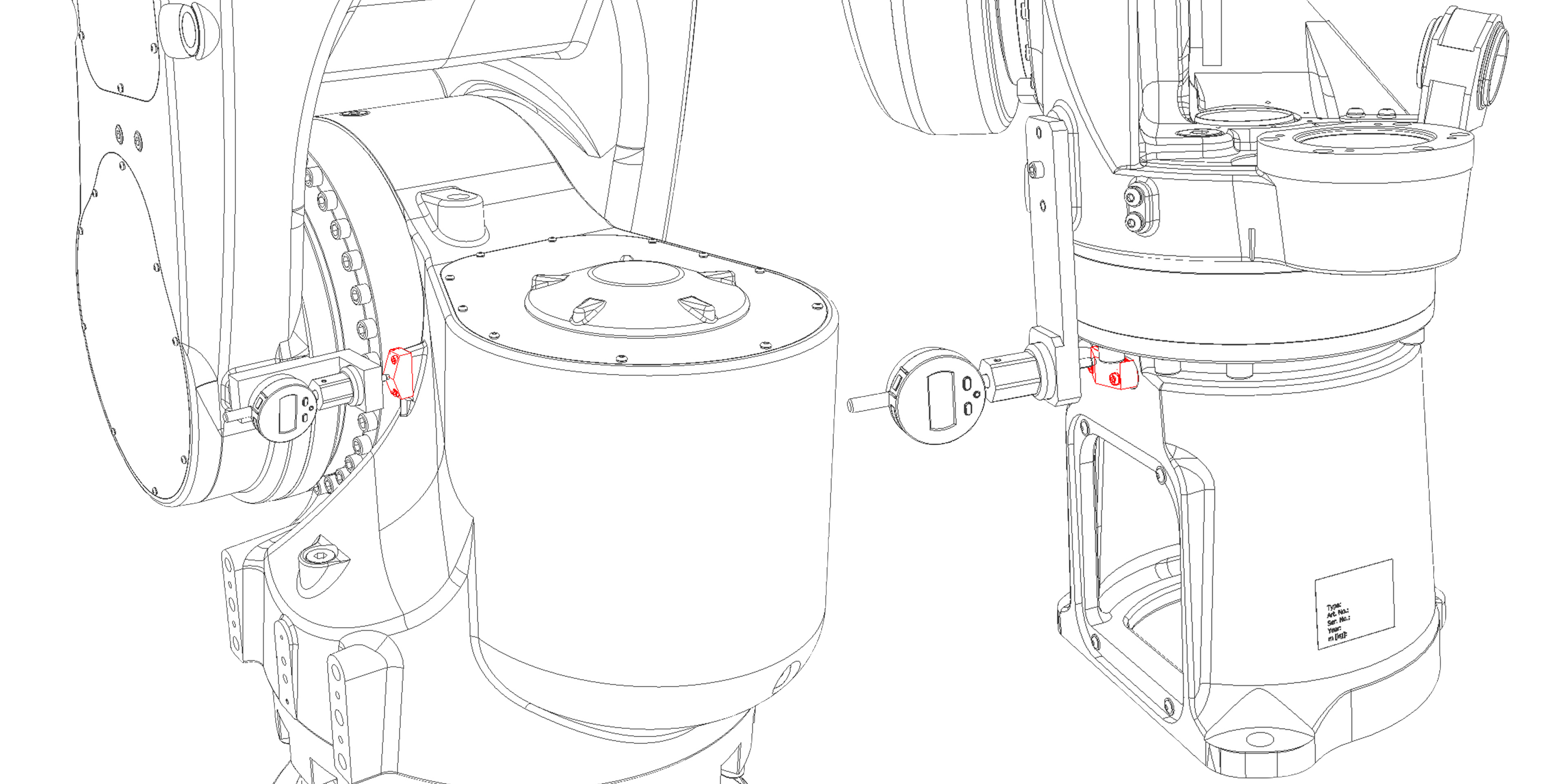

This type of robot is based on the principle of serial kinematics.

All drives and motor cables are moved along. The robot has three (3) translational and three (3) rotational degrees of freedom. This robot mechanics was developed for applications that require high rigidity, good vibration damping and maximum precision. In the kinematics, axes 2, 3 and 5 are supported on both sides, which increases the rigidity accordingly. This model is sealed against abrasive dusts, liquids, etc. and can be pressurized with sealing air. Media supplies for the end effector can be routed protected inside the robot structure.

Scope of delivery

- Robot mechanics incl. gearbox

- Free installation of drive technology provided (including incoming goods inspection)

- Multi-hour, logged test run as final quality inspection

- Threaded protection caps

- Transport and packing instructions

Required accessories

- Set of parts for installing the drive technology. This set consists of, for example, a servo motor adapter, servo motor cable, transmission input pinion, plug board (usually on the base frame).

Note: The operating instructions and documentation on commissioning, service, maintenance, etc. are available in the password-protected download area of the respective product page (www.autonoxfinder.com).

-

Signed in / logged in you will receive further documents:

Note: If the documentation in the download area is not yet complete, please contact us (info@autonox.com).

| Field of application: | Standard (not hygienic), CNC Robotics |

|---|---|

| Kinematics: | Serial |

| Translatory Degrees of Freedom (X,Y,Z): | 3 |

| Rotational Degrees of Freedom (α,ß,γ): | 3 |

| Nominal payload [kg|lbs]: | 150 | 330.7 |

| Supplementary load on the arm [kg|lbs]: | 50 | 110.2 |

| Working area-reach [mm|in]: | 2390 | 94.1 |

| Lubricants of the bearings: | Synthetic |

| Lubricants of the gearboxes: | Synthetic |

| Integrated media supply to the end effector possible: | Yes |

| Cleaning: | No high pressure |

| Protection class: | Axis 1: IP66, from axis 2: IP67 |

| Ambient temperature [°C|°F]: | 0 to +40 | +32 to +104 |

| Relative humidity level [%]: | 95 (free of condensation) |

| Mounting position: | Floor, Ceiling |

| Robot weight without drive engineering (esp. drive) [kg|lbs]: | 793 | 1748.3 |

| Special features: | Developed for applications that demand high rigidity, good vibration damping and maximum precision. Sealed against abrasive dusts, liquids, etc. Can be pressurized with sealing air. |

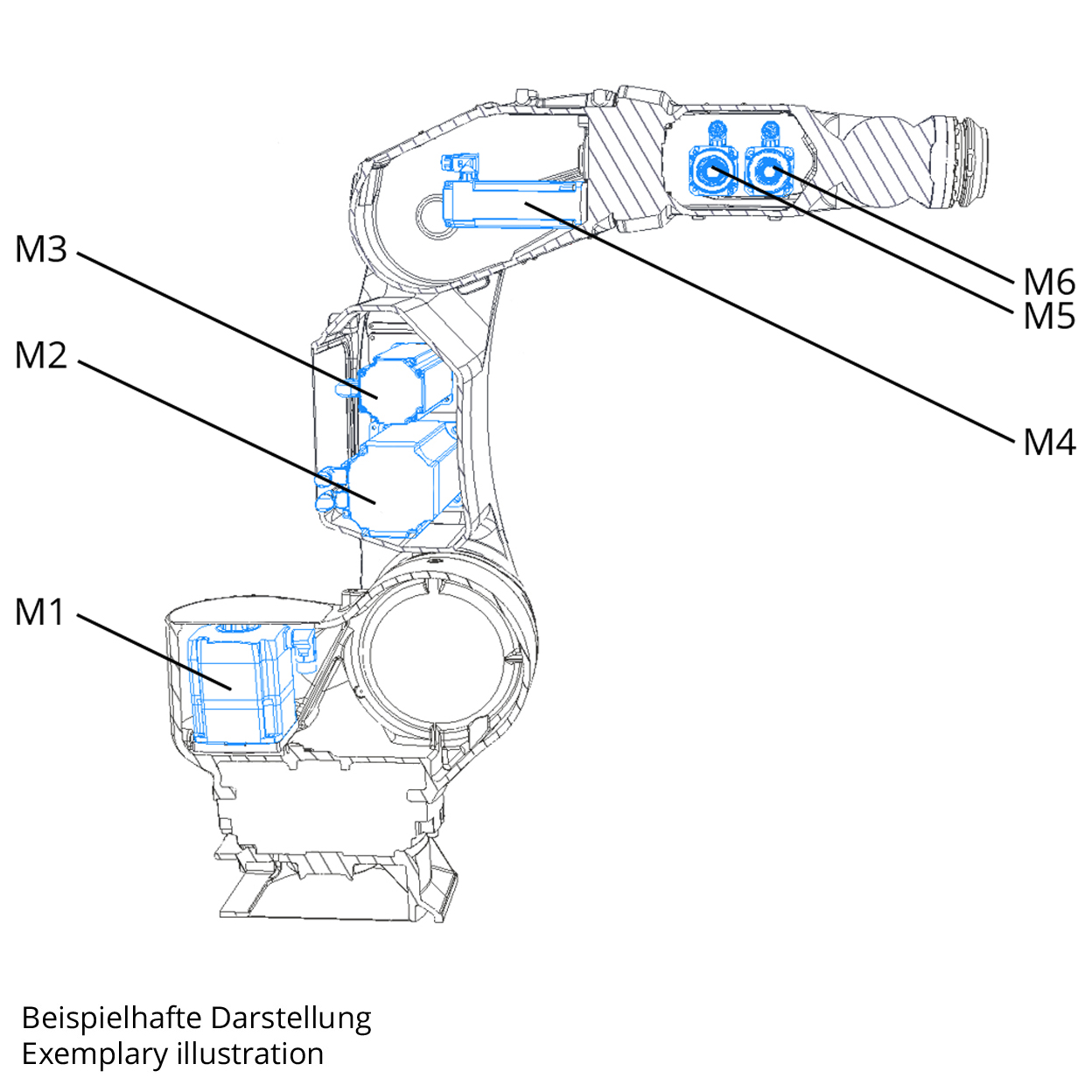

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | AM8062-3LH1-0000 |

| M2 | AM8072-1TH1-0000 |

| M3 | AM8054-1MH1-0000 |

| M4 | AM8052-1JH1-1001 |

| M5 | AM8043-1KH1-0000 |

| M6 | AM8042-1JH1-0000 |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | MS2N07-C1BRN-CMUK1-NNNNN-NN |

| M2 | MS2N07-E0BNN-CMVL2-NNNNN-NN |

| M3 | MS2N07-C0BNN-CMUL1-NNNNN-NN |

| M4 | MS2N05-D0BRN-CMDL1-NNNNN-NN |

| M5 | MS2N05-C0BTN-CMDL1-NNNNN-NN |

| M6 | MS2N05-B0BTN-CMDL1-NNNNN-NN |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | DMS2-190-0280-30-B15MP2-J000-0 |

| M2 | DMS2-190-0360-30-B15MP2-J000-0 |

| M3 | DMS2-142-0160-45-B15MP2-Q000-0 |

| M4 | DMS2-100-0100-60-B15MP2-Q000-0 |

| M5 | DMS2-100-0060-60-B15MP2-Q000-0 |

| M6 | DMS2-100-0060-60-B15MP2-Q000-0 |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | 1FK7101-2AF71-1CB2-Z N05 |

| M2 | 1FK7105-2AF71-1CB0-Z N05 |

| M3 | 1FK2106-6AF10-1MB0 |

| M4 | 1FK7062-2AH71-1CB0-Z N05 |

| M5 | 1FK2205-4AF10-1MB0 |

| M6 | 1FK2205-4AF10-1MB0 |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

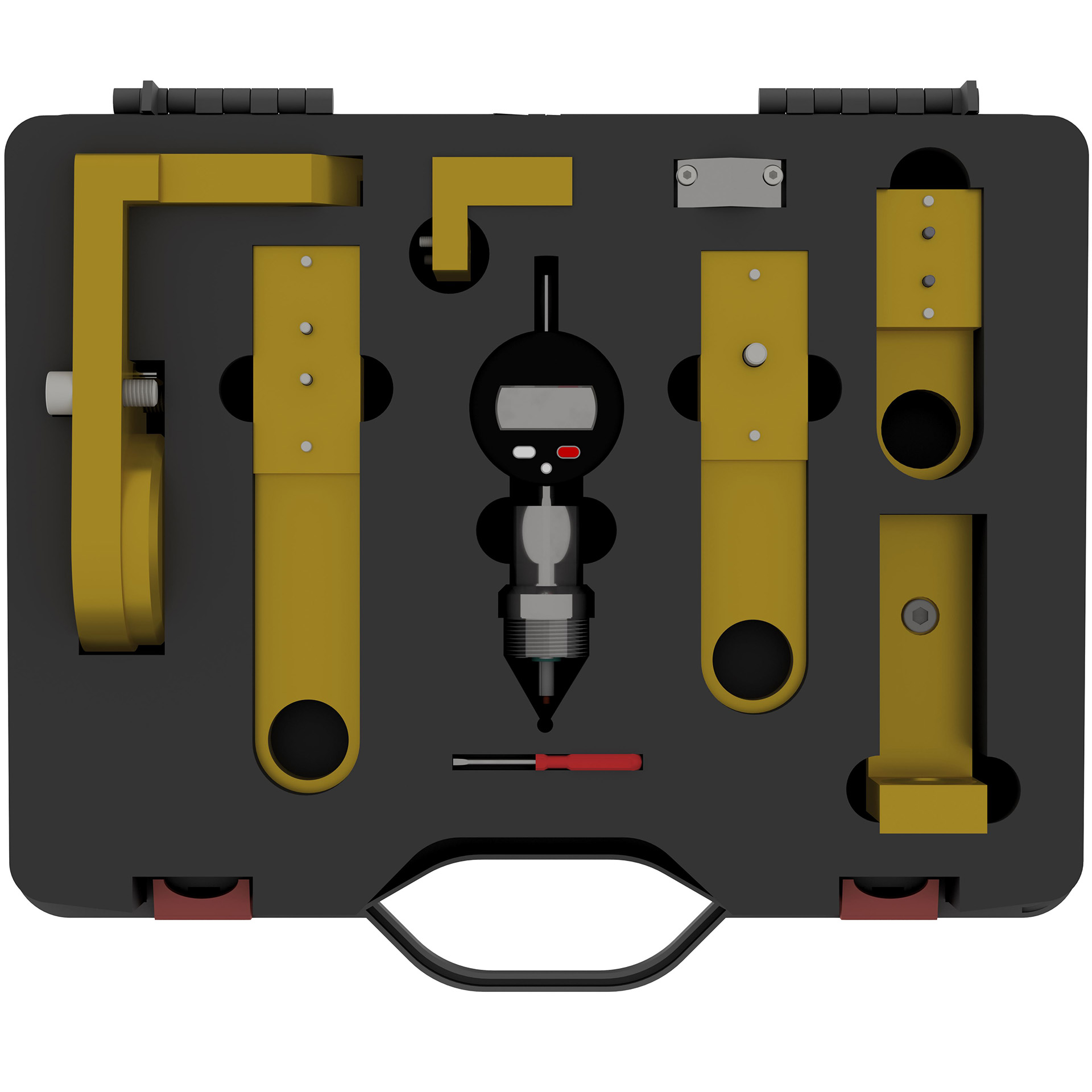

This calibration set contains all the calibration devices required for calibrating the robot mechanics as well as a handy protection case with a special inlay. The case is ideal for storing and transporting these devices.

Scope of delivery

Calibration set consisting of:

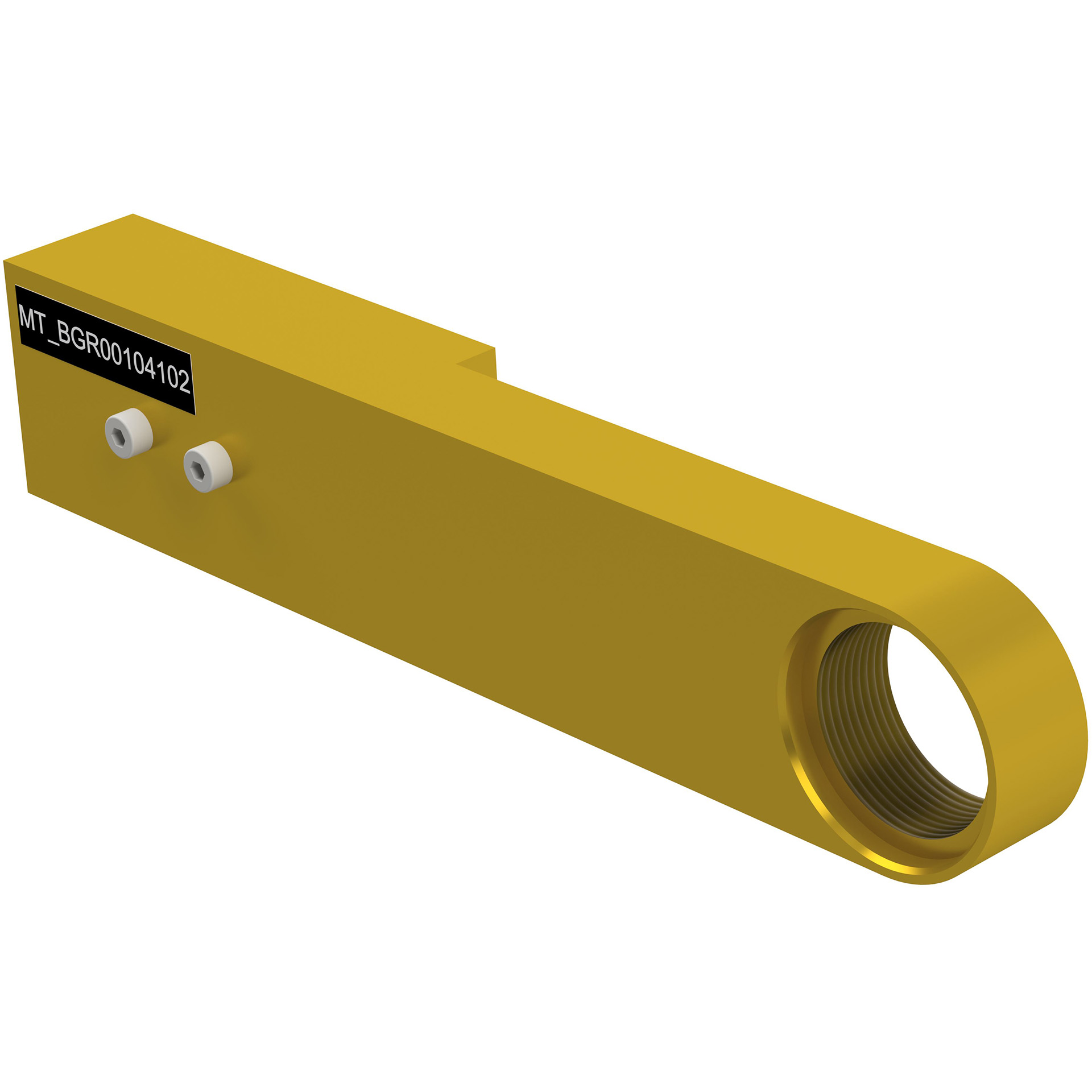

- Calibration device MT_BGR00104102

- Calibration device MT_BGR00104099

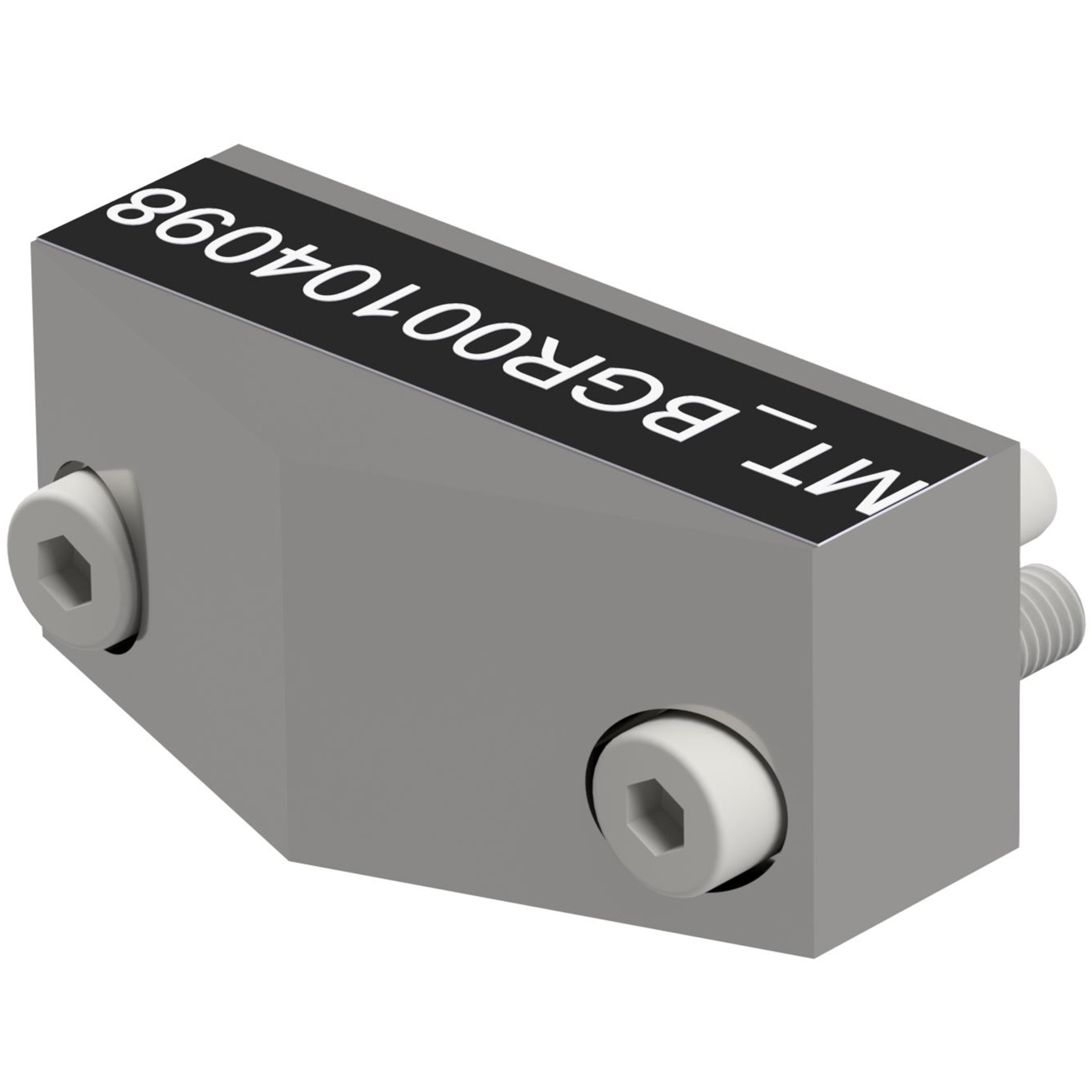

- Calibration device MT_BGR00104098

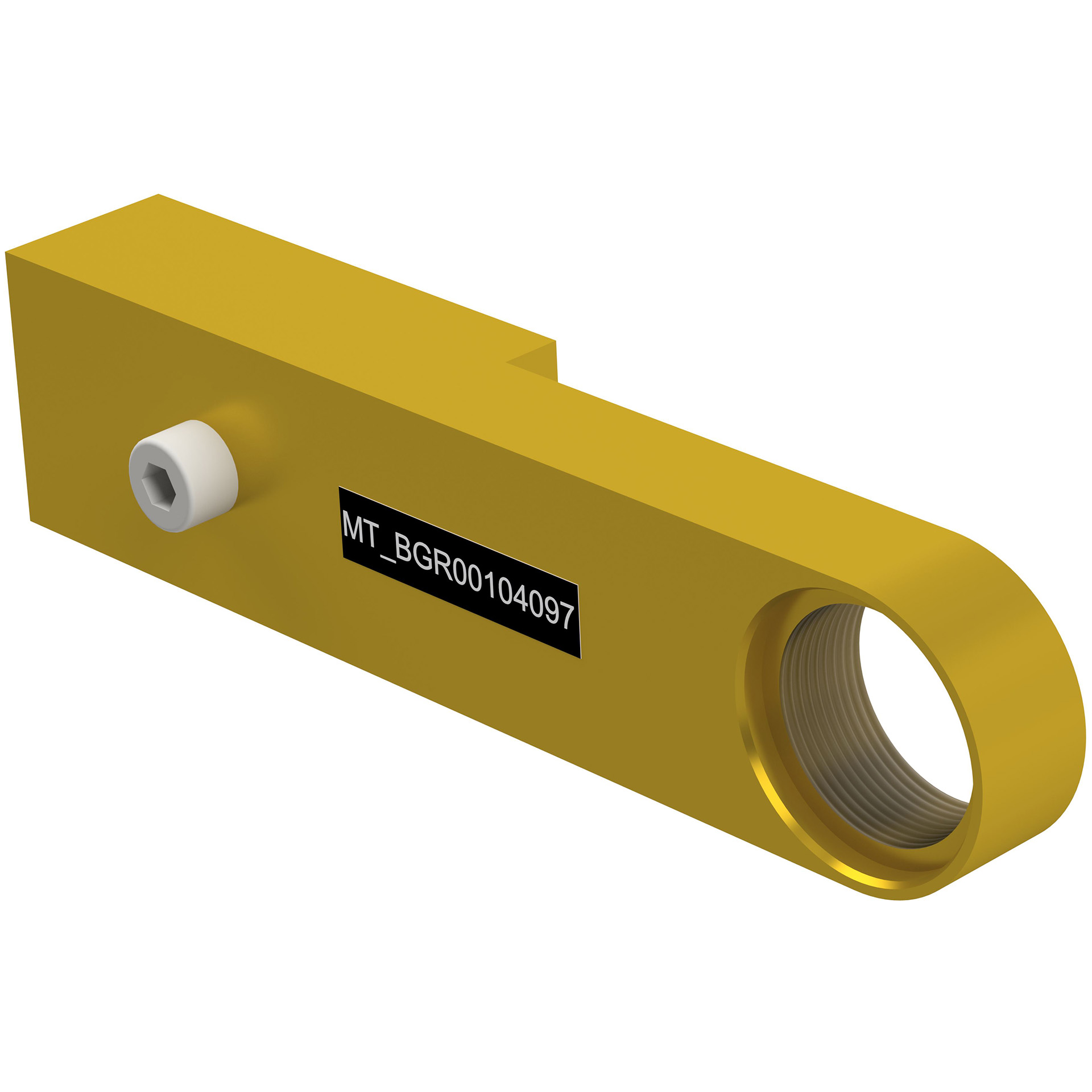

- Calibration device MT_BGR00104097

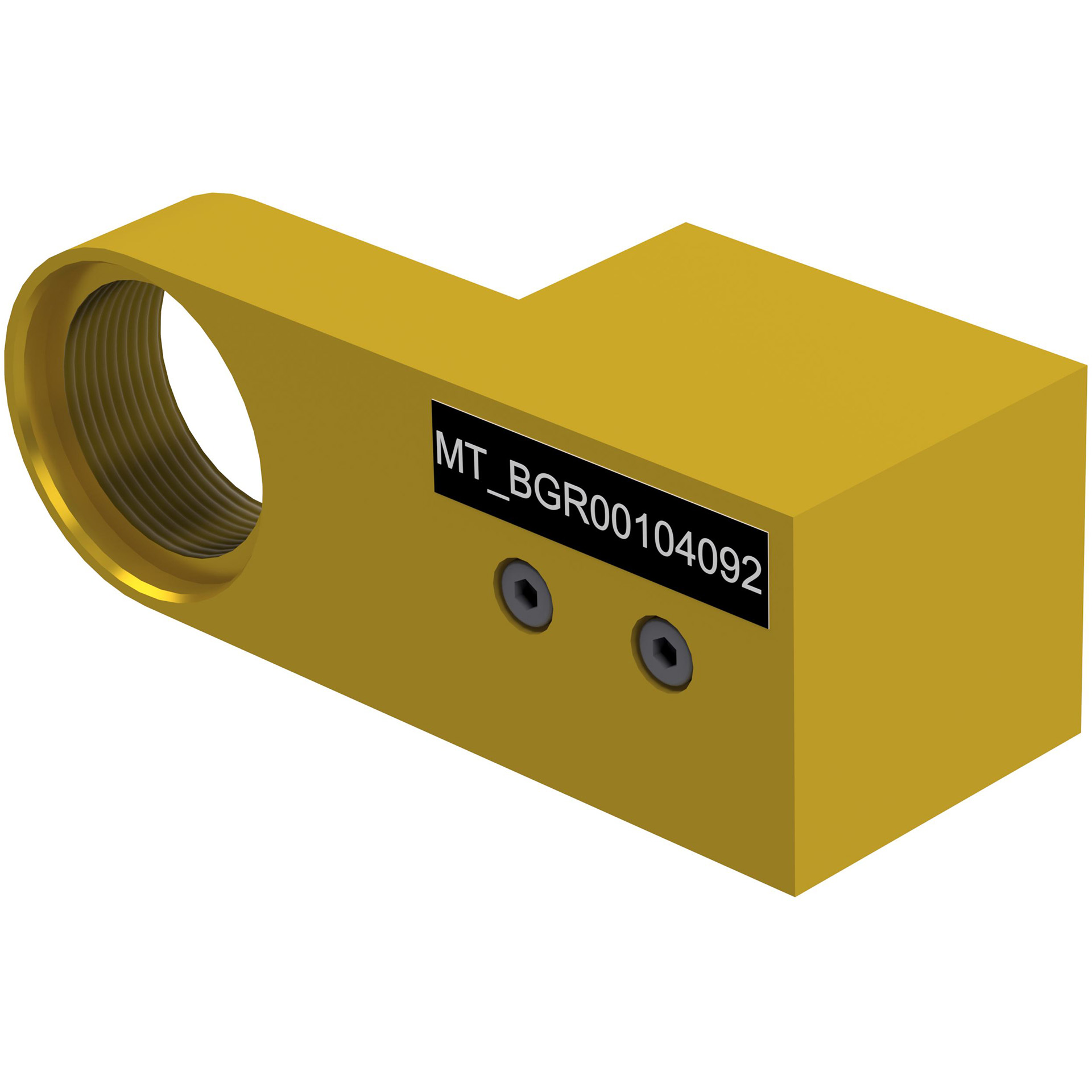

- Calibration device MT_BGR00104092

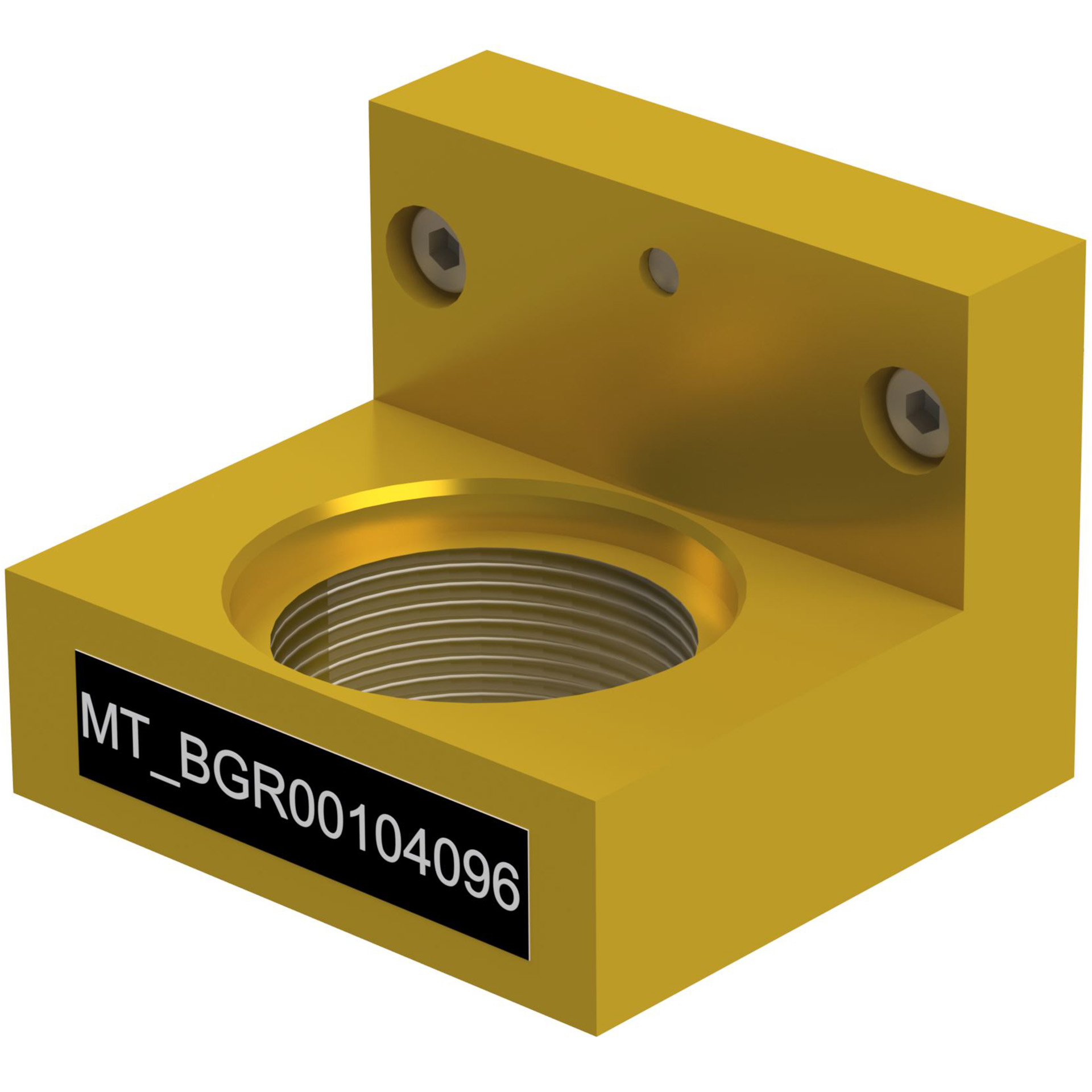

- Calibration device MT_BGR00104096

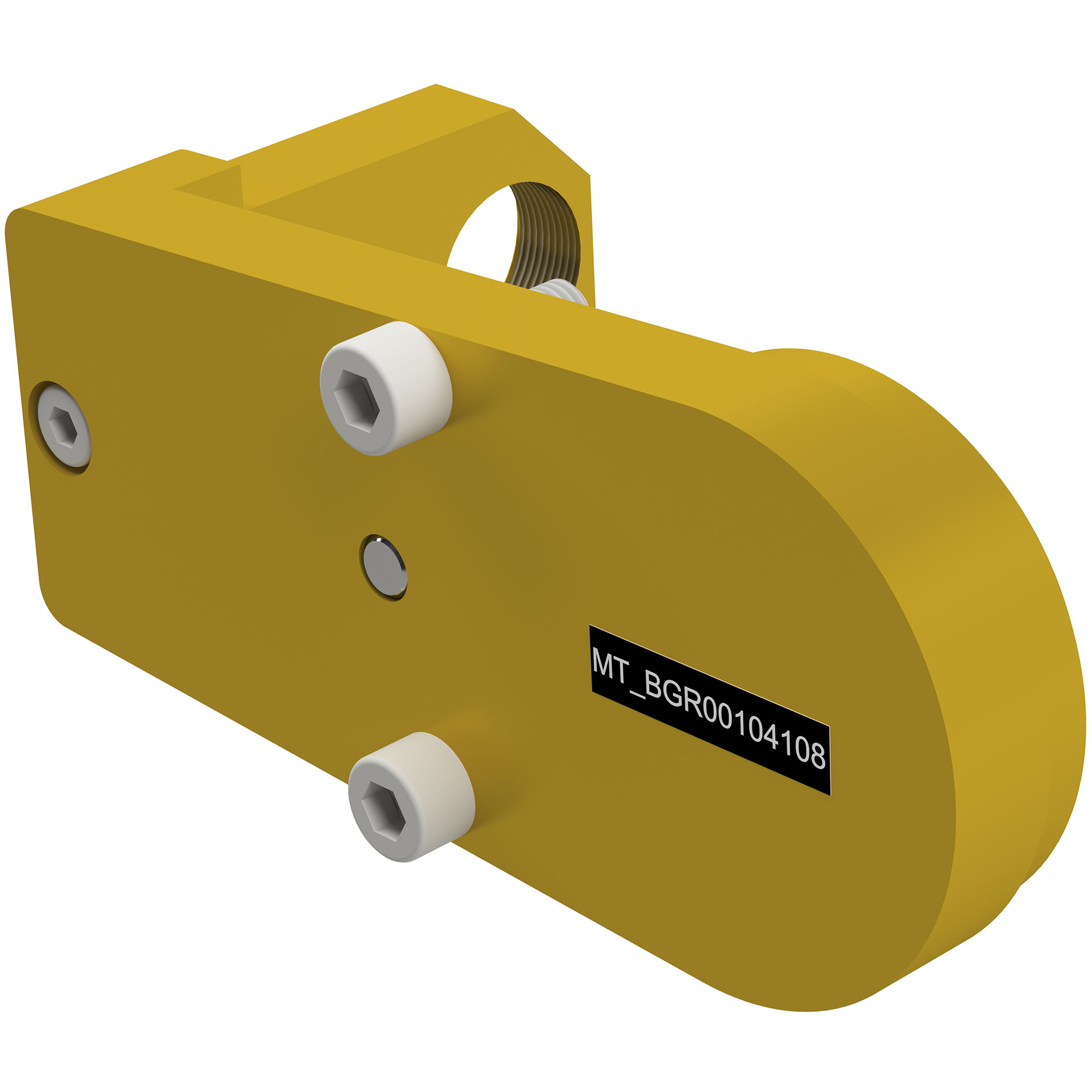

- Calibration device MT_BGR00104108

- Calibration device MT_BGR00020307

- Protection case with inlay

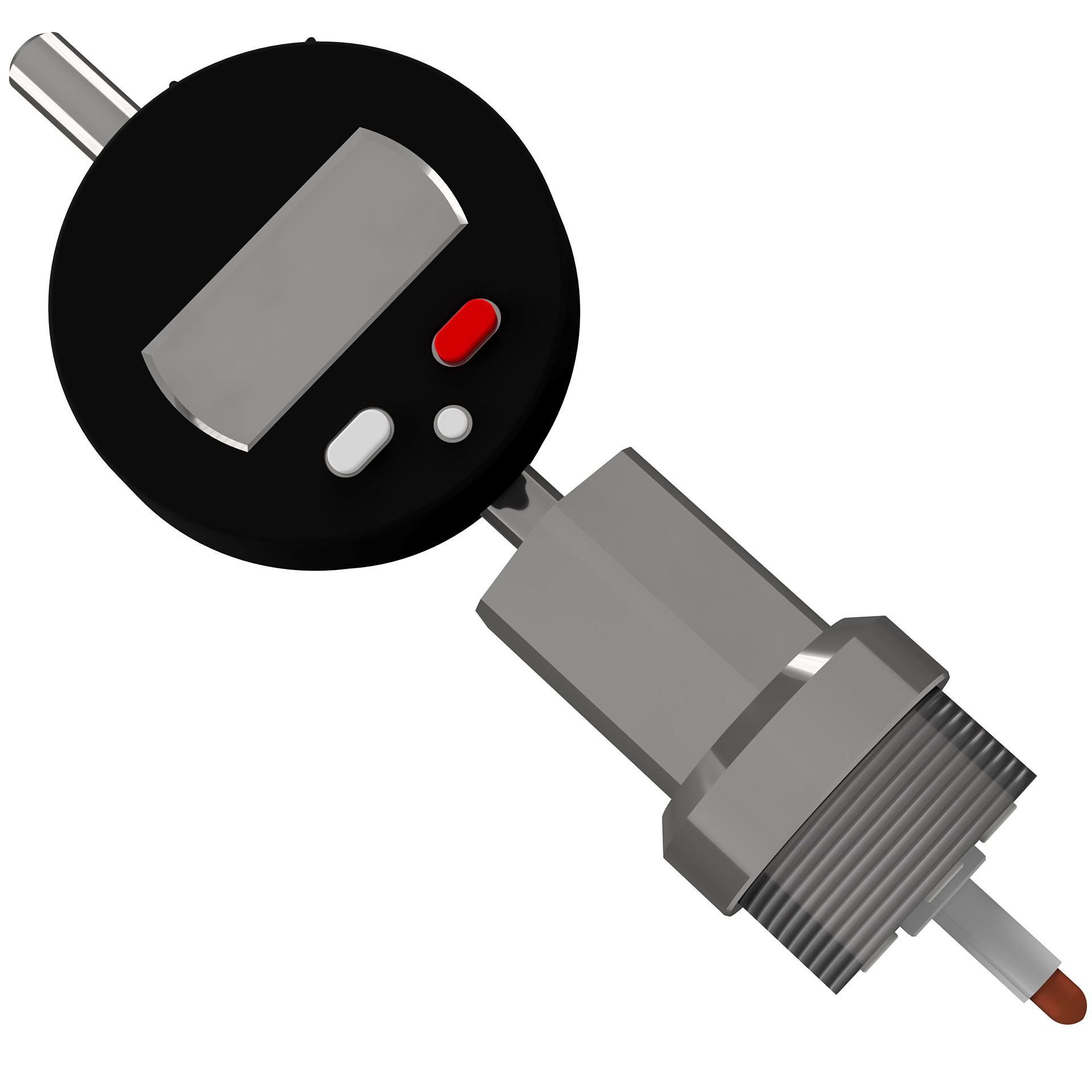

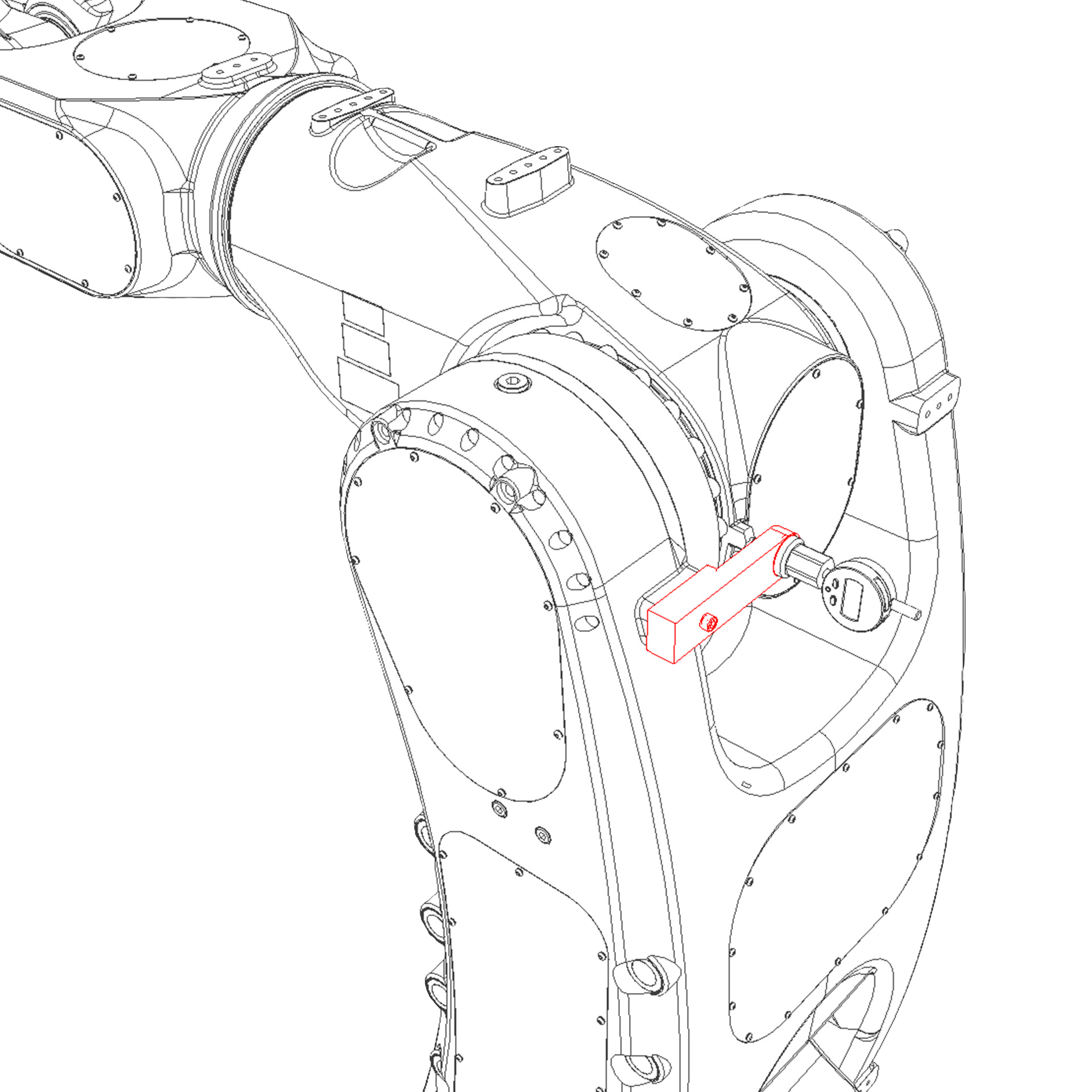

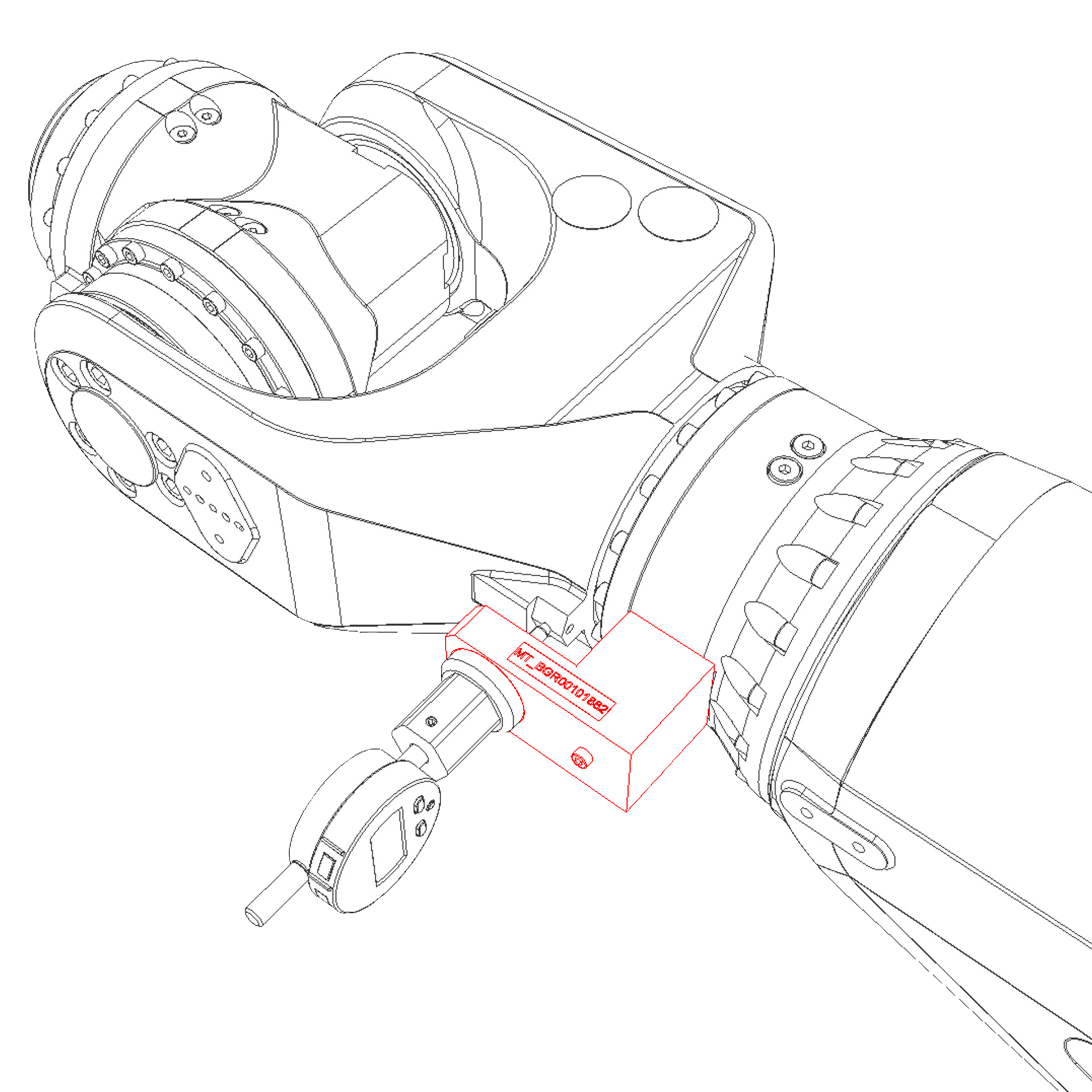

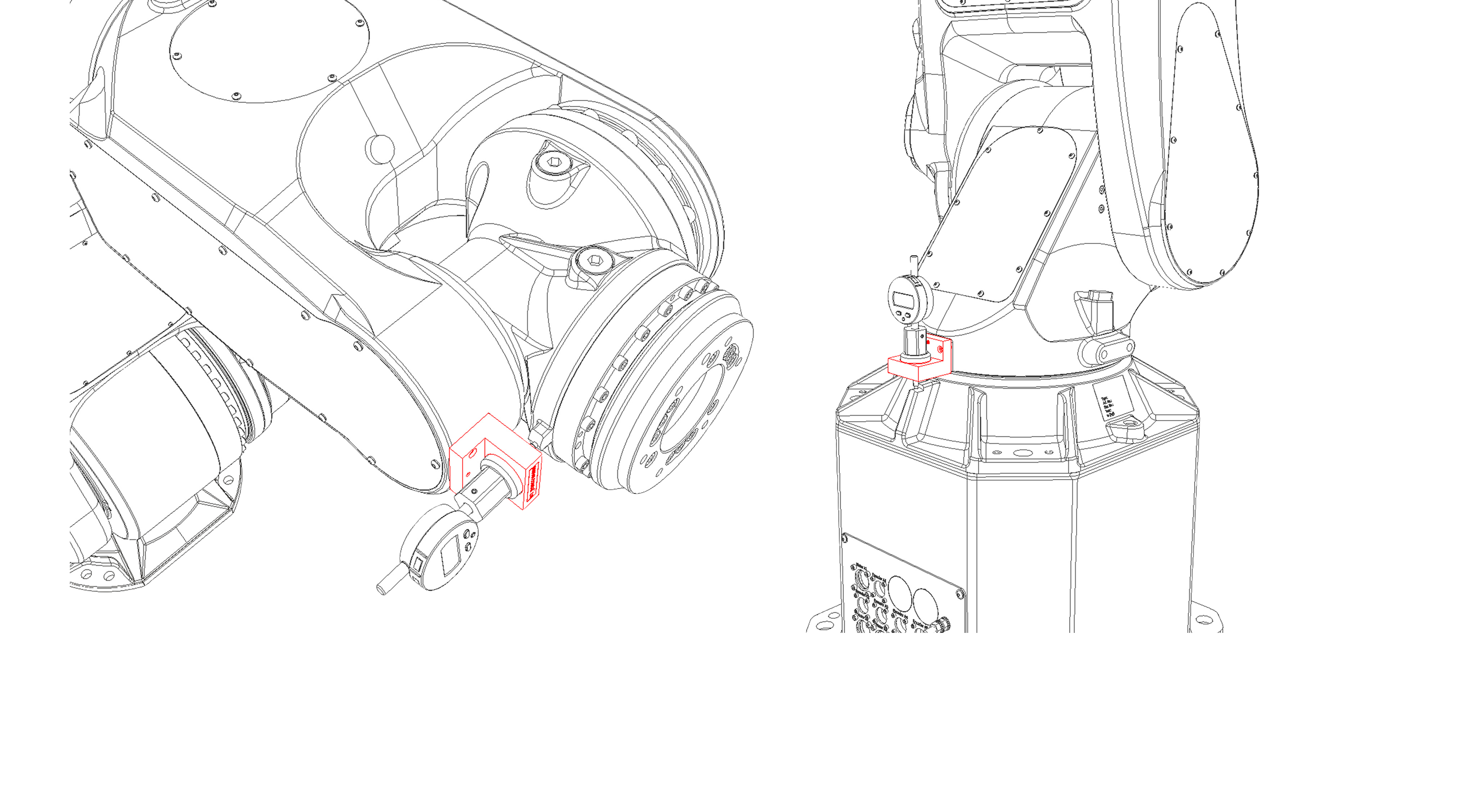

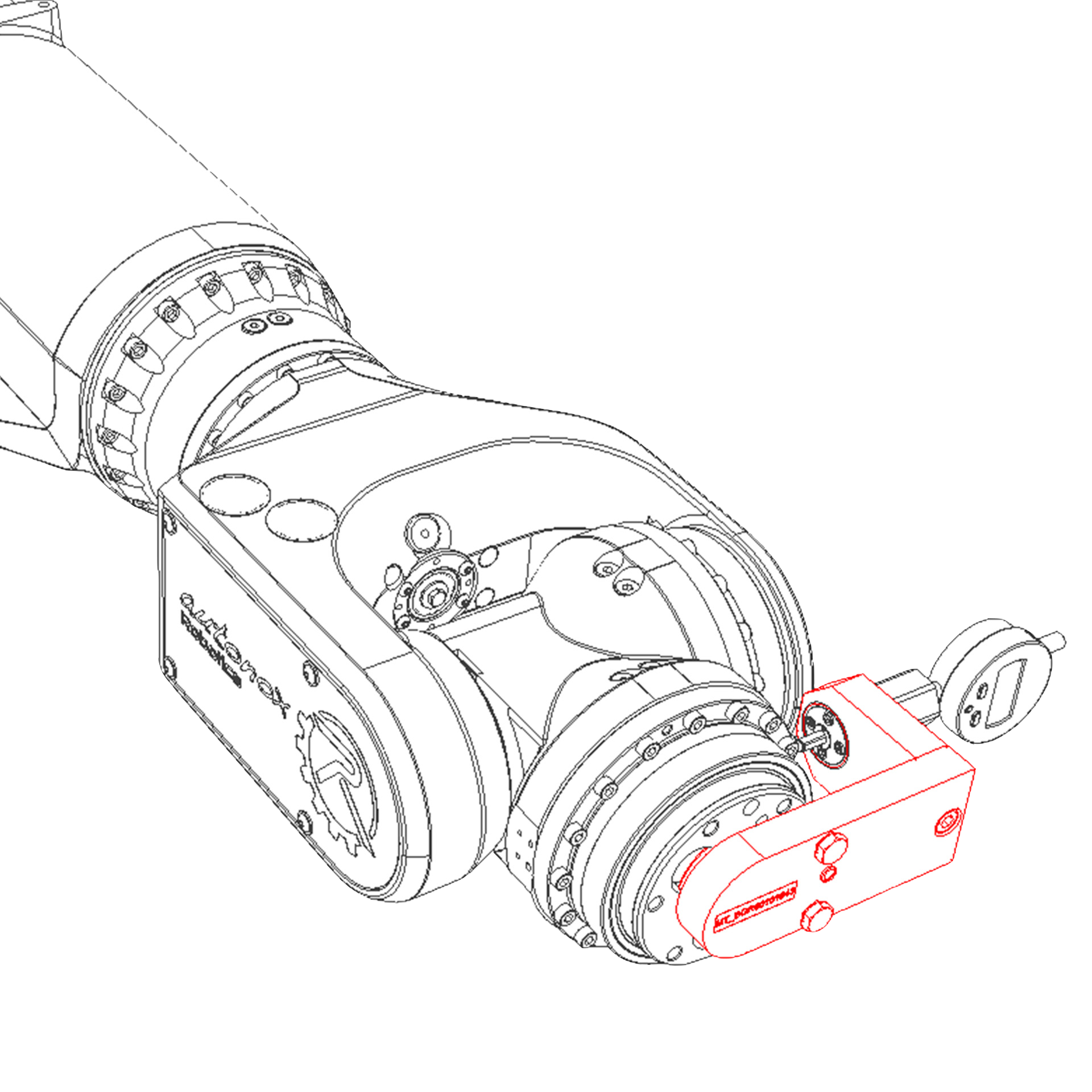

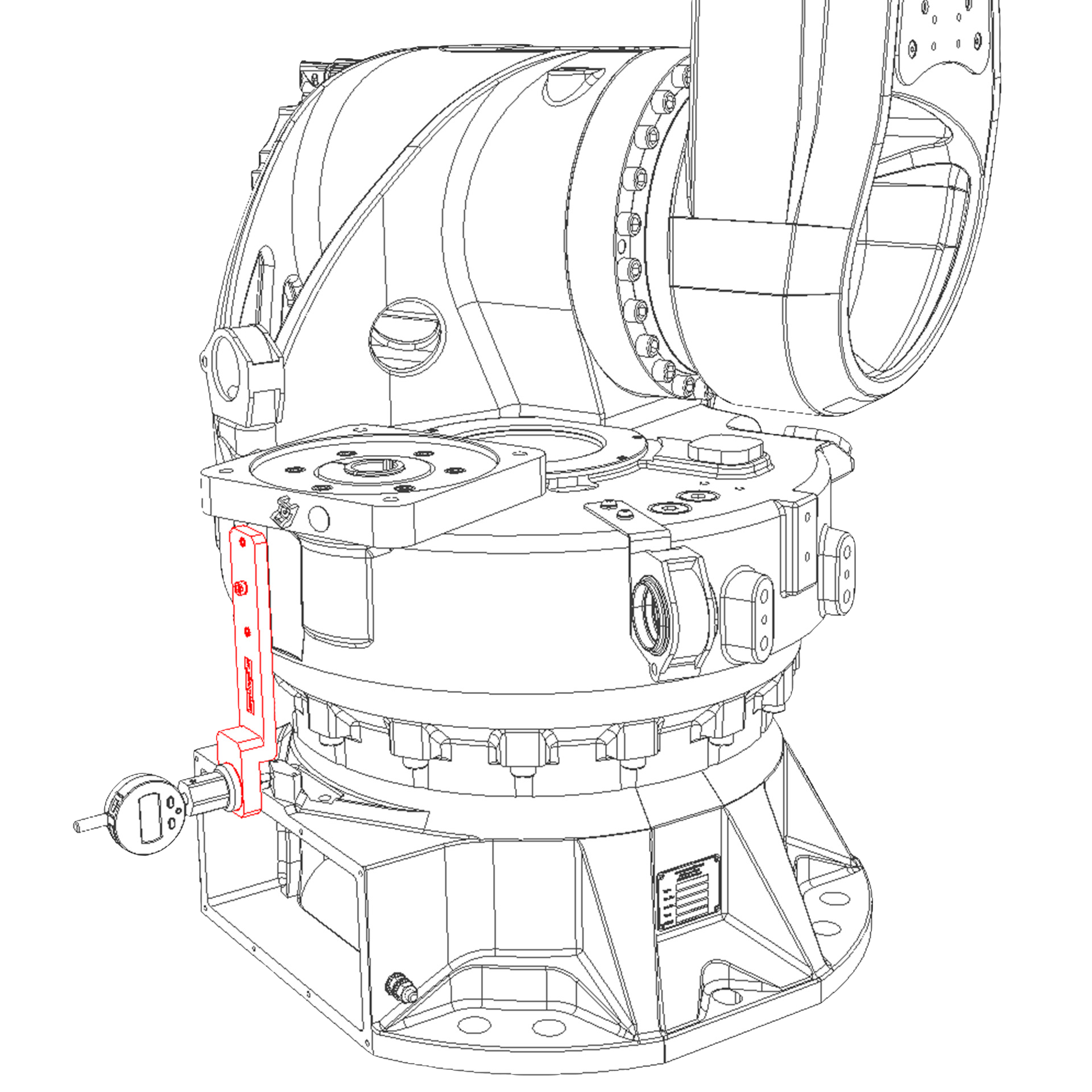

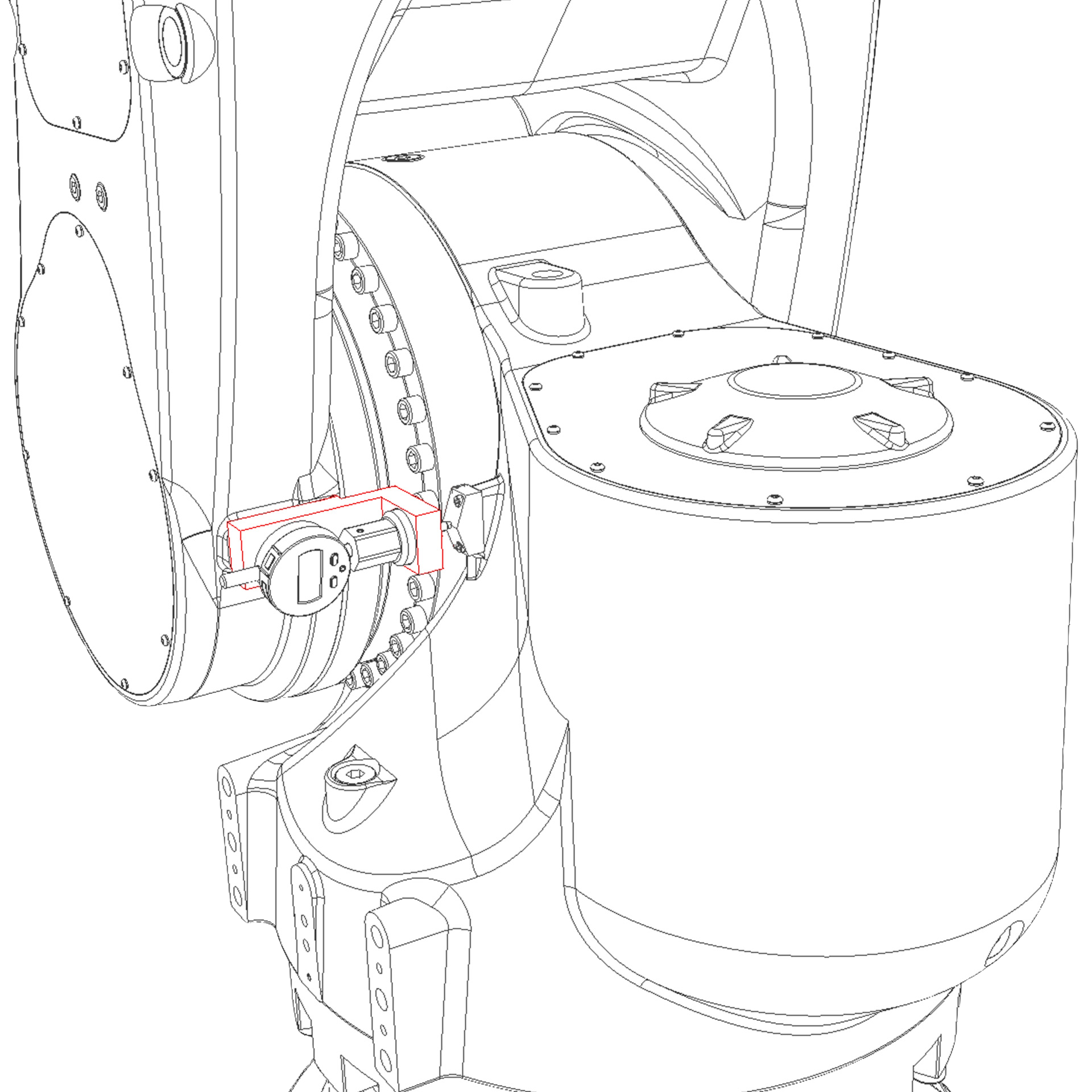

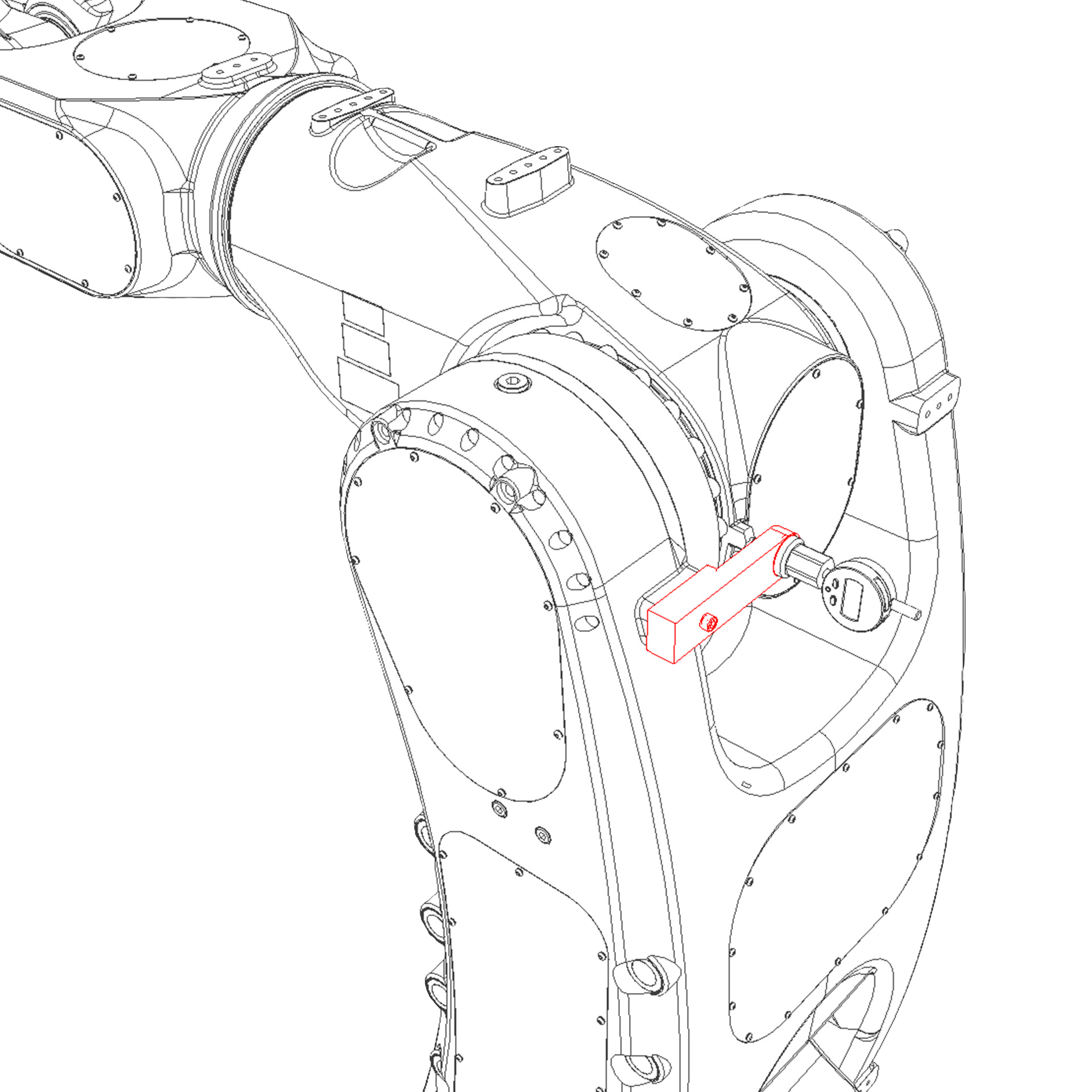

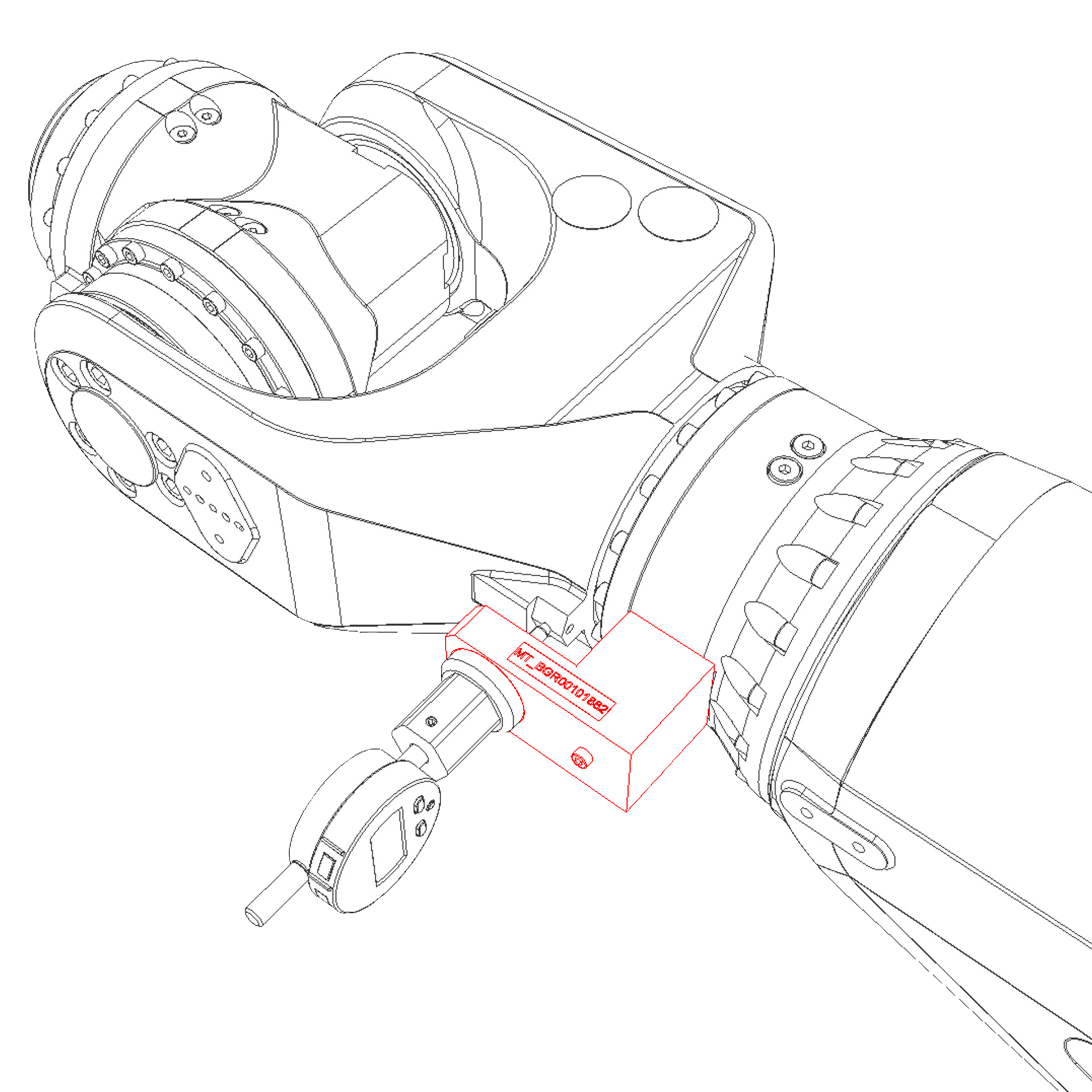

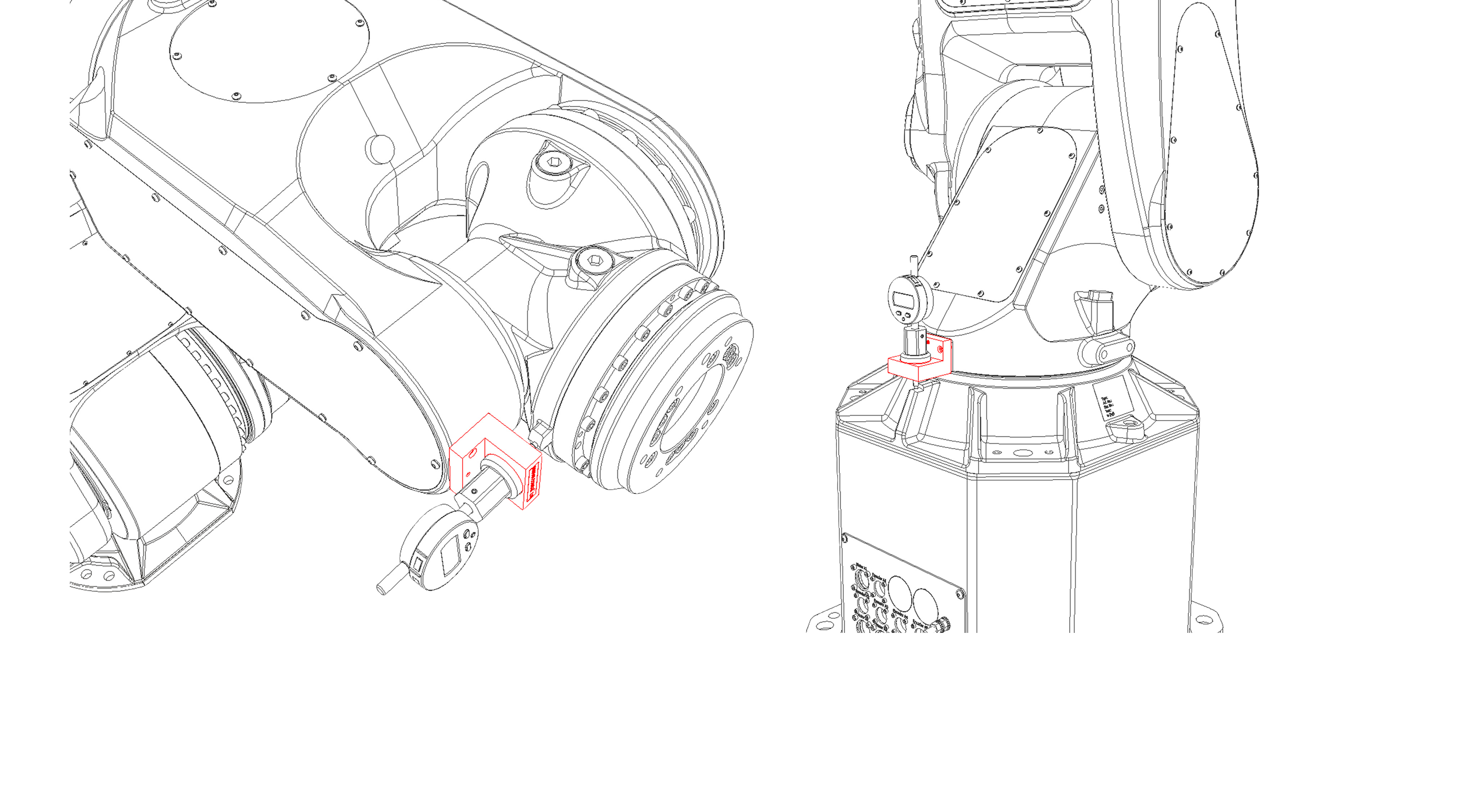

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. It is equipped with a digital dial gauge and is used to read out the measured values in connection with other calibration devices. The measured values can be read out safely outside the machine via RS232, USB, Digimatic and an additional extension cable. The calibration instructions can be found in the download area of the respective robot mechanics.

Scope of delivery

- Calibration device

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

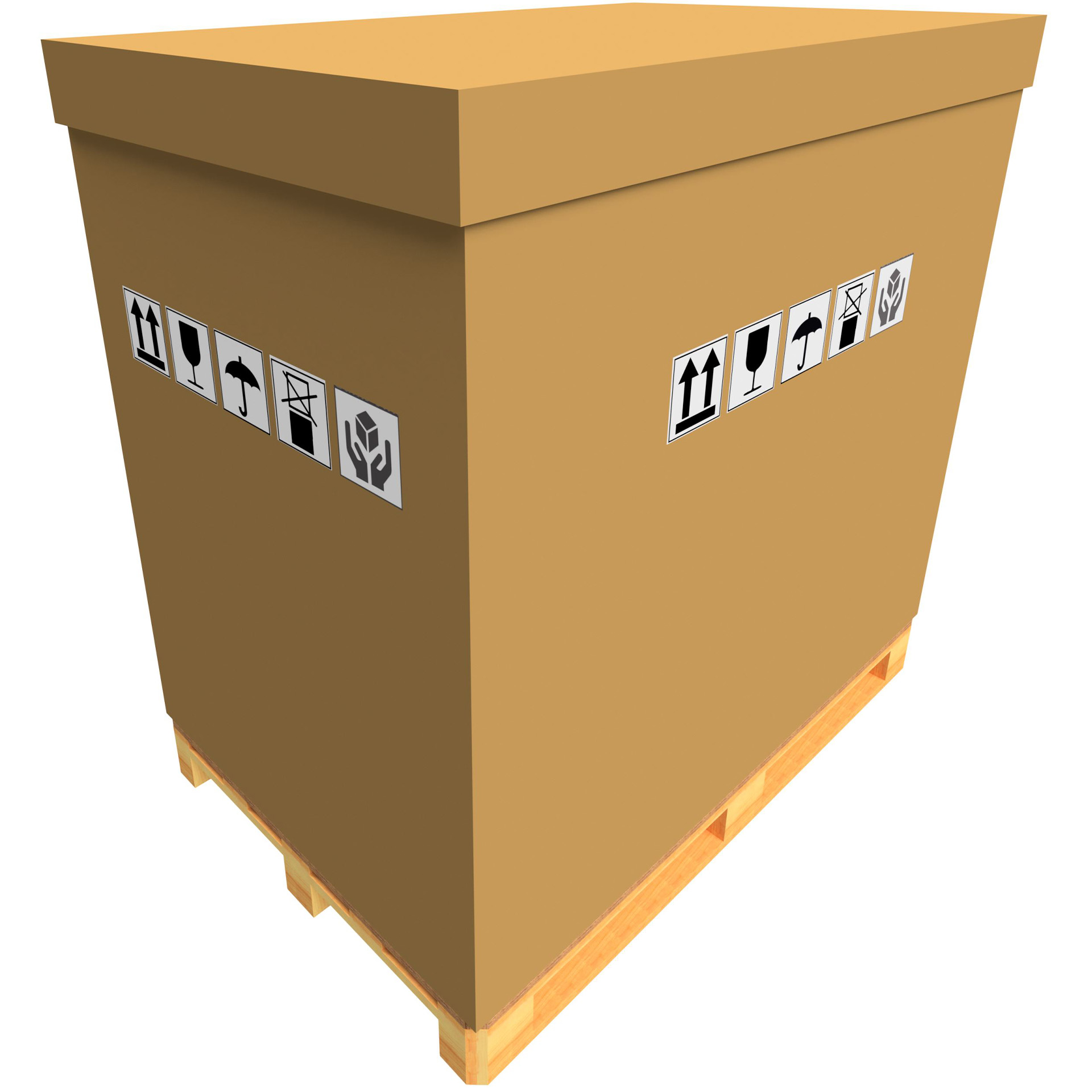

This carrier box is necessary for transporting the robot mechanics and is only suitable for transport by land.

Scope of delivery

- Carrier box incl. assembling/transport aid

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This carrier box is necessary for transporting the robot mechanics. It can be used for transport by land, air and sea.

Scope of delivery

- Carrier box incl. assembling/transport aid

This type of robot is based on the principle of serial kinematics.

All drives and motor cables are moved along. The robot has three (3) translational and three (3) rotational degrees of freedom. This robot mechanics was developed for applications that require high rigidity, good vibration damping and maximum precision. In the kinematics, axes 2, 3 and 5 are supported on both sides, which increases the rigidity accordingly. This model is sealed against abrasive dusts, liquids, etc. and can be pressurized with sealing air. Media supplies for the end effector can be routed protected inside the robot structure.

Scope of delivery

- Robot mechanics incl. gearbox

- Free installation of drive technology provided (including incoming goods inspection)

- Multi-hour, logged test run as final quality inspection

- Threaded protection caps

- Transport and packing instructions

Required accessories

- Set of parts for installing the drive technology. This set consists of, for example, a servo motor adapter, servo motor cable, transmission input pinion, plug board (usually on the base frame).

Note: The operating instructions and documentation on commissioning, service, maintenance, etc. are available in the password-protected download area of the respective product page (www.autonoxfinder.com).

| Field of application: | Standard (not hygienic), CNC Robotics |

|---|---|

| Kinematics: | Serial |

| Translatory Degrees of Freedom (X,Y,Z): | 3 |

| Rotational Degrees of Freedom (α,ß,γ): | 3 |

| Nominal payload [kg|lbs]: | 150 | 330.7 |

| Supplementary load on the arm [kg|lbs]: | 50 | 110.2 |

| Working area-reach [mm|in]: | 2390 | 94.1 |

| Lubricants of the bearings: | Synthetic |

| Lubricants of the gearboxes: | Synthetic |

| Integrated media supply to the end effector possible: | Yes |

| Cleaning: | No high pressure |

| Protection class: | Axis 1: IP66, from axis 2: IP67 |

| Ambient temperature [°C|°F]: | 0 to +40 | +32 to +104 |

| Relative humidity level [%]: | 95 (free of condensation) |

| Mounting position: | Floor, Ceiling |

| Robot weight without drive engineering (esp. drive) [kg|lbs]: | 793 | 1748.3 |

| Special features: | Developed for applications that demand high rigidity, good vibration damping and maximum precision. Sealed against abrasive dusts, liquids, etc. Can be pressurized with sealing air. |

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | AM8062-3LH1-0000 |

| M2 | AM8072-1TH1-0000 |

| M3 | AM8054-1MH1-0000 |

| M4 | AM8052-1JH1-1001 |

| M5 | AM8043-1KH1-0000 |

| M6 | AM8042-1JH1-0000 |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | MS2N07-C1BRN-CMUK1-NNNNN-NN |

| M2 | MS2N07-E0BNN-CMVL2-NNNNN-NN |

| M3 | MS2N07-C0BNN-CMUL1-NNNNN-NN |

| M4 | MS2N05-D0BRN-CMDL1-NNNNN-NN |

| M5 | MS2N05-C0BTN-CMDL1-NNNNN-NN |

| M6 | MS2N05-B0BTN-CMDL1-NNNNN-NN |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | DMS2-190-0280-30-B15MP2-J000-0 |

| M2 | DMS2-190-0360-30-B15MP2-J000-0 |

| M3 | DMS2-142-0160-45-B15MP2-Q000-0 |

| M4 | DMS2-100-0100-60-B15MP2-Q000-0 |

| M5 | DMS2-100-0060-60-B15MP2-Q000-0 |

| M6 | DMS2-100-0060-60-B15MP2-Q000-0 |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

Motor |

Manufacturer article number (Specification) |

|---|---|

| M1 | 1FK7101-2AF71-1CB2-Z N05 |

| M2 | 1FK7105-2AF71-1CB0-Z N05 |

| M3 | 1FK2106-6AF10-1MB0 |

| M4 | 1FK7062-2AH71-1CB0-Z N05 |

| M5 | 1FK2205-4AF10-1MB0 |

| M6 | 1FK2205-4AF10-1MB0 |

Suitable motors must be provided by the customer to autonox for assembly free of charge.

-

Signed in / logged in you will receive further documents:

Note: If the documentation in the download area is not yet complete, please contact us (info@autonox.com).

This calibration set contains all the calibration devices required for calibrating the robot mechanics as well as a handy protection case with a special inlay. The case is ideal for storing and transporting these devices.

Scope of delivery

Calibration set consisting of:

- Calibration device MT_BGR00104102

- Calibration device MT_BGR00104099

- Calibration device MT_BGR00104098

- Calibration device MT_BGR00104097

- Calibration device MT_BGR00104092

- Calibration device MT_BGR00104096

- Calibration device MT_BGR00104108

- Calibration device MT_BGR00020307

- Protection case with inlay

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. It is equipped with a digital dial gauge and is used to read out the measured values in connection with other calibration devices. The measured values can be read out safely outside the machine via RS232, USB, Digimatic and an additional extension cable. The calibration instructions can be found in the download area of the respective robot mechanics.

Scope of delivery

- Calibration device

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This carrier box is necessary for transporting the robot mechanics and is only suitable for transport by land.

Scope of delivery

- Carrier box incl. assembling/transport aid

This device is used to calibrate our robot mechanics. A defined motor position (encoder value) is assigned to the respective mechanical axis position. The calibration instructions can be found in the download area of the respective robot mechanics.

- Calibration device

- Mounting set (consisting of: Screw(s) and/or pin(s))

This carrier box is necessary for transporting the robot mechanics. It can be used for transport by land, air and sea.

Scope of delivery

- Carrier box incl. assembling/transport aid